The rapid shortening of days starting in mid-August drives the soybean to maturity. The minimum temperature for soybean seed ripening is 8 to 9°C, with an optimum temperature of 19 to 20°C. Cool temperatures (<10°C) during seed fill can negatively affect soybean yield by reducing seed size and delaying maturity.

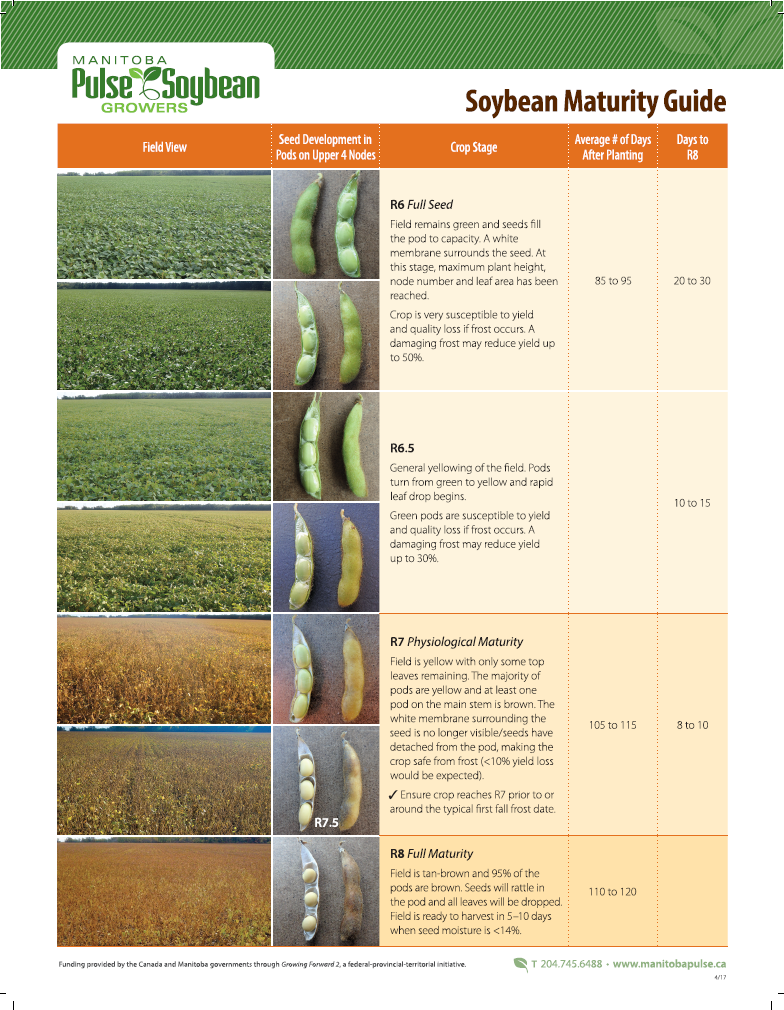

Soybeans are susceptible to frost in early fall. A light frost of 0°C to -1°C may kill top leaf growth but should not harm pods and seeds. Temperatures below -1 °C for extended periods can damage green stems, pods, and seeds, reducing yield and quality. Soybeans are most susceptible during the reproductive stage R5 to R6. In the R6 stage (whole seed), plants are still green, and the top nodes are still filling. At this stage, frost may reduce yield by up to 50%. In the R6.5 stage, when seeds have finished filling at the top of the plant, and the bottom leaves are starting to drop, but the pods are still green/yellow, frost damage could reduce yields by up to 30%. At R7, soybeans reach physiological maturity, and frost may reduce quality due to green seed, but it would have a less than 10% impact on yield.

Soybeans begin to mature as defoliation begins. Leaves start to dry and fall from the main stem, while pods turn brown. When fully mature, soybean seeds will rattle in the pods when shaken. Timing of the harvest is crucial, and while the ideal moisture content for storage and harvest is 13%, harvesting can commence when the moisture content reaches 20%. Delaying harvest until seeds have <13% moisture is not advisable, as the risk of shatter loss, splits, and reduced overall quality increases significantly when seeds are too dry.

It is recommended that soybeans be straight-cut because swathing increases shattering losses, and swaths are prone to blowing. If maturity is uneven, or green weedy material is a concern, several registered pre-harvest products can be used.

When setting the combine for soybean harvest, the concave clearance and cylinder speed should be set to avoid seed cracking. Reel speed and ground travel speed should be synchronized to prevent cutter bar shatter. Floating cutter bars can also help reduce losses. Cutting as low to the ground as possible will help capture low pods. Checking for losses on the ground is important (only four beans per square foot on the ground equals one bu/ac of yield). Adjustments should focus on gathering in the header area, as that accounts for more than 80% of the harvest loss. Loss should ideally be less than 5% of the total yield.

If harvest occurs when soybean moisture is above 13%, the soybeans should be dried to reduce moisture. If using a grain dryer, care must be taken to avoid over-drying the soybeans to prevent excess shrinkage. Dried grain needs to be cooled down using fans or aeration after drying. When drying soybeans with natural air in an aeration system, it is best to use a whole aeration floor to ensure even airflow and drying. Bins should be temperature monitored to ensure no heating occurs. Using conveyors and avoiding overhandling can also help prevent cracking and damaging the seeds, which can result in increased dockage at the grain elevator.

Grading factors for soybeans include foreign material, test weight, damage (heated, mouldy, splits), downy mildew, and mixed colours.