By Bruce Barker, PAg

Good management of peas, lentils, faba beans, chickpeas, dry beans, and soybeans in storage will help maintain the value of your crop.

Moisture Specifications

The Canadian Grain Commission (CGC) sets seed moisture content for grading and storage purposes. Most pulse crops are considered to be dry enough for safe storage at the CGC dry grade (Table 1). Processors also generally follow the same CGC moisture specifications when purchasing seed.

Table 1. Canadian Grain Commission Moisture Specifications

| Peas | Green Lentils | Red Lentils | Faba Beans | Chickpeas | Beans | Soybeans | |

|---|---|---|---|---|---|---|---|

| Dry | < 16 | < 14 | < 13 | < 16 | < 14 | < 15 | < 14 |

| Tough | 16.1 – 18 | 14.1 – 16 | 13.1 – 16.0 | 16.1 – 18 | 14.1 – 16 | 15-18 | 14.1 – 16.0 |

| Damp | > 18 | > 16 | > 16 | > 18 | > 16 | > 18 | 16.1 – 18 |

Source: Canadian Grain Commission

Seed Moisture Content at Harvest

Because many pulse crops crack or split when harvested at dry seed moisture content or lower, harvesting at the tough seed moisture stage is sometimes recommended to reduce seed damage. Subsequent aeration is then required to dry the crop down for safe storage.

Peas: Threshing peas at 18 to 20 per cent seed moisture content is recommended to lower the risk of seed cracking or peeling and reduce shatter losses. Threshing over 20 per cent moisture can increase the amount of earth tag. Seed damage will increase as the seed moisture goes below 16 per cent.

Lentils: Combining green lentils at 16 to 18 per cent moisture is considered ideal, assuming drying to 14 per cent can be accomplished.

Faba Beans: Faba bean harvest can start at 18 to 20 per cent moisture, but seed should be aerated down to 16 per cent moisture for safe storage.

Chickpeas: Chickpea combining can start when seed reaches about 18 per cent moisture. Avoid combining chickpeas that are wet or immature. Chickpea seed colour is an important grading factor. The stage of the crop should be closely monitored, as harvesting too early increases the chance of green seed in the crop, which lowers the grade and value of the grain. Deductions are implemented if immature green seeds comprise more than 0.5 per cent in Kabuli, and more than one per cent in Desi chickpeas.

Dry Beans: To minimize seed damage during threshing, dry beans should be combined when the seed is at a moisture content of 16 to 22 percent. For long-term storage moisture content of beans should be at 14 per cent and 16 per cent moisture is acceptable for short-term storage.

Soybeans: Direct combine soybeans when the pods are dry and the seeds are hard. Combining can take place when seed moisture is below 20 per cent, but soybeans should be stored at less than 14 per cent. Seed damage is high when soybeans are harvested at less than 12 per cent moisture, and harvest losses can also be high under dry conditions.

Aeration and Drying

General recommendations for aeration and drying follow the same recommendations for cereals and oilseeds. Natural air can be effectively used to remove moisture from pulses and may actually work better than for cereals because of reduced static pressure. Given the correct temperature and relative humidity, natural air drying can be successfully used to dry and/or cool pulses to safe storage moisture content and temperature.

Because pulses are generally harvested early, the weather works well for effective natural air drying, and there is no need for additional heat with a supplemental heating system. If supplemental heating is being used, limit the temperature increase to 10°C or less, and ensure you are using a Canadian Standards Association (CSA) certified heating system.

Safe Storage Moisture and Temperatures

The foundation for long-term storage is dry, cool grain. The Canadian Grain Commission (CGC) sets seed moisture content for grading and storage purposes. Most pulse crops are considered to be dry enough for safe storage at the CGC dry grade. Processors also generally follow the same CGC moisture specifications when purchasing seed.

Crop stored under cool, dry conditions can be stored for long periods, but as seed moisture or temperature rises, storage length becomes less. The drier and cooler the grain, the safer it is during storage. The target temperature for all grains provided they are dry is 15°C or lower.

Noel White, formerly with the Cereal Research Centre with Agriculture and Agri-Food Canada at Winnipeg developed safe storage charts for different grains, including peas. Pea storage information has been extrapolated to cover green and red lentils.

Even if the crop went into the bin dry, cooling with aeration will help extend the safe storage timeframe, and is especially important for longer-term storage. For example, using the safe storage charts, green lentils at 14 per cent moisture content and at a 20°C temperature could be safely stored for about 23 weeks, but if the temperature was cooled to 10°C , the lentils could be safely stored for 80 weeks.

Peas: See Table 2 for safe storage details.

Lentils and Chickpeas: As moisture levels decline, especially in Kabuli chickpea types, seed begins to shrink from the seed coat and becomes more susceptible to damage in handling at less than 13 per cent (Table 3).

Dry Beans: Spoilage occurs when initial temperature ranges from 5°C to 42°C with respective moisture from 20 to 10 per cent moisture content. Moisture content of 18 per cent or less is recommended for safe storage of dry beans. Dry beans are often stored and traded at 17 per cent moisture content, but are considered dry at 16 per cent. Drying beans below seed moisture content of 16 per cent makes the seed coat more fragile and susceptible to cracking or splitting when handled.

Beans can also be discounted if they are too dry (below 15 per cent moisture) (Table 4).

Soybeans: The safe storage moisture content for commercial seed is 13 per cent for storage up to one year and 10 per cent for storage up to five years. These guidelines do not take into consideration such things as accumulation of fines under the spout lines (Table 5).

Table 2. Number of Weeks for Safe Storage of Peas at the Specified Grain Moisture Content and Storage Temperature

| Temperature (°C) | Moisture Content of Seed (%) | ||||

| 12 | 14 | 16 | 18 | 21 | |

| Maximum Safe Storage (Weeks) | |||||

| 26 | 31 | 16 | 7 | 4 | 2 |

| 20 | 55 | 28 | 13 | 7 | 4 |

| 16 | 100 | 50 | 20 | 12 | 6 |

| 10 | 200 | 95 | 38 | 20 | 21 |

| 6 | 370 | 175 | 70 | 39 | 20 |

Source: Sokhansanj, 1995

Table 3. Number of Weeks for Safe Storage of Lentils at the Specified Grain Moisture Content and Storage Temperature

| Temperature (°C) | Moisture Content of Seed (%) | |||||

| 12 | 13 | 14 | 16 | 18 | 21 | |

| Maximum Safe Storage (Weeks) | ||||||

| 25 | 31 | 16 | 13 | 7 | 4 | 2 |

| 20 | 55 | 28 | 23 | 13 | 7 | 4 |

| 15 | 100 | 50 | 40 | 20 | 12 | 6 |

| 10 | 200 | 95 | 80 | 38 | 20 | 21 |

| 5 | 370 | 175 | 150 | 70 | 39 | 20 |

Source: Extrapolated from pea data (Sokhansanj 1995)

Red lentil will be similar to pea (McVicar, 2006)

Table 4. Estimated Number of Weeks for Decreased Germination to Occur in Dry Beans

| Temperature (°C) | Moisture Content of Seed (%) | |||||||

| 11 | 12 | 13 | 14 | 16 | 18 | 20.5 | 23 | |

| Maximum Safe Storage (Weeks) | ||||||||

| 25 | 31 | 22 | 16 | 11 | 7 | 4 | 2 | 0.5 |

| 20 | 55 | 40 | 28 | 19 | 13 | 7 | 3.5 | 1.5 |

| 15 | 100 | 75 | 50 | 30 | 20 | 12 | 6 | 3 |

| 10 | 20 | 14 | 95 | 60 | 38 | 20 | 11 | 4.5 |

| 5 | 37 | 27 | 170 | 110 | 70 | 39 | 20 | 9 |

Source: Extrapolated from pea data, Sokhansanj, 1995

Table 5. Length of Safe Storage for Soybeans Depending on Target Use of Seed

| Moisture Content (%) | Market Stock | Seed Stock |

|---|---|---|

| 10 – 11 | 4 years | 1 year |

| 10 – 12.5 | 1 to 3 years | 6 months |

| 13 – 14 | 6 to 9 months | Questionable, check germination |

| 14 – 15 | 6 months | Questionable, check germination |

Source: Protection of Farm-Stored Grains, Oilseeds, and Pulses from Insects, Mites, and Moulds. Agriculture and Agri-Food Canada, 1851/E (revised)

Artificial Heat Grain Drying

For peas and lentils, air temperatures should not exceed 45°C to preserve germination. The sample should not be dried more than four to five percentage points per pass through the dryer. For beans, supplemental heat drying temperatures should be restricted to a maximum of 27°C to 32°C to avoid germination loss. Faba beans should be dried at a maximum of 32°C and should be done in two stages if more than five per cent moisture content is removed. The maximum safe drying temperatures are 43°C for soybeans intended for seeding purposes, and 49°C for soybeans intended for commercial use.

Storage Length and Quality

When conditioned properly, pulses can be stored for up to two years. However, pulses, especially those that contain tannins in their seed coats can oxidize over time, losing colour and grade.

Peas (except for maple and dun varieties), Kabuli chickpeas, zero-tannin faba beans, and zero-tannin lentils have zero-tannin seed coats so these should store well. Alternatively, lentil varieties with green seed coats are susceptible to discolouration and grade reduction with age.

Discolouration is a function of oxidation and light degradation. Producers should store lentils in dry, dark conditions. Ensuring proper cool, dry, and dark storage conditions may help lengthen the time before any discolouration occurs.

It is advised that lentils, particularly green lentils, not be stored through a second summer season, in order to avoid excessive discolouration and downgrading. Seed from successive years should not be mixed as the oldes seed may cause downgrading to the entire sample.

Handling

Pulses should be moved as little as possible, and handled gently to reduce chipping and splits. Use belt conveyors instead of augers if possible. If using augers, run the auger full and at a reduced speed. Use bean ladders on equipment to minimize the dropping of seed from more than a few feet.

Lentil, faba bean, pea, and dry bean seed should not be handled at temperatures below –20°C, as the seed is more susceptible to chipping and peeling at low temperatures.

The irregular shape of chickpeas really must have gentle movement in order to keep from breaking the beaks from the seed coat, and to ensure that the seed coat integrity is not damaged.

Frost Damaged Pulses

The same considerations for safe storage apply to frost damaged pulses. Dry and cool to safe moisture and temperature levels. Special consideration should be given if green seed or green weed seeds are present. Generally, the lower the quality (and higher the level of fines, etc.), the more likely you will see formation of hot spots or localized areas of spoilage that may spread to the rest of the bin.

Monitoring

Source: Canola Council of Canada

Stored pulses should be monitored regularly for hot spots and other changes in moisture and temperature. A variety of manual and automated systems are available to help keep track of seed condition. Peas and chickpeas often respire or sweat after being placed in storage. Extra care should be taken to monitor the grain inside the bin for moisture build-up or spoilage.

Moisture levels should be tested often for large Kabuli chickpea types, because seed testing dry can sometimes hide seed with higher moisture levels internally in the grain mass. Monitor regularly for hot spots and other changes in moisture and temperature. A variety of manual and automated systems are available to help keep track of seed condition.

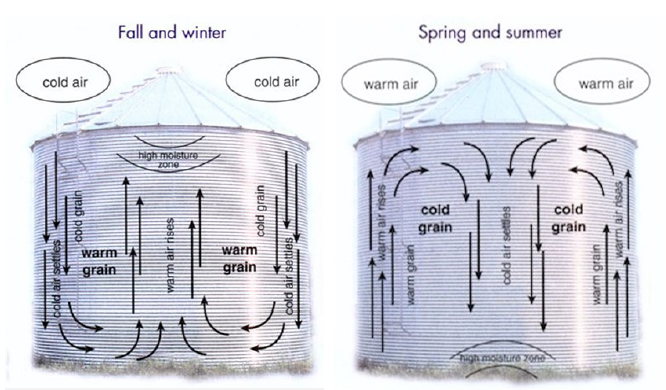

During the winter, cold air moves downward along the outside of the bin and moves warm, moist air up through the core of the grain bin. Pulse growers should monitor their bins, especially where high moisture may concentrate. If high moisture areas become a concern, recommendations for other crops like canola include moving one-third of the bin to disrupt the moisture cycle and help cool the centre grain mass.

In the spring, the opposite moisture migration cycle occurs. Warm air moves upwards along the bin walls and cold air carries moisture down the core of the bin, concentrating moisture near the centre/bottom of the bin. This can create potential concentrations of warm, moist air where spoilage may begin.

The Prairie Agricultural Machinery Institute in Humboldt researched canola and found that there was no advantage to aeration in the spring with very dry canola. Temperature changes occurred within the bin, but no moisture migration was observed. Leaving the bin alone was the best strategy. Whether this would be the same for peas, lentils, and chickpeas is unknown, as pulses are stored at a higher moisture content and have larger seed size, which may allow moisture migration to occur. The best advice is to continually monitor bins for any high moisture concentration.

Stored Grain Insects

Stored grain insects are generally not a problem in pulses that are stored under dry, cool conditions. Blaine Timlick with the CGC says that while there are several weevils that exist in Canada, in 20+ years he has only seen pulses infested on three occasions. This includes railcar delivery into terminal monitoring, and the sampling/ testing that the CGC performs during vessel loading.

In general, all bins should be monitored not only for moisture and temperature, but also the presence of insects. Timlick suggests that if the temperature and moisture are managed, then quality should be maintained for taste and nutritional value.

Insects very rarely infest pulse crops. Monitoring should take place as standard practice. When monitoring pulse bins, insects that could be watched for include: vetch weevil (Bruchus brachialis Fahr), pea weevil (Bruchus pisorum (L.)), broadbean weevil (Bruchus rufimanus Boh), and bean weevil (Acanthoscelides obtectus (Say)).