By Tom Wolf, Agrimetrix Research & Training

The spraying industry has undergone a lot of change in the past years. The introduction of low-drift nozzles and pulse-width-modulation (PWM) has been very important, and of course, the switch from pull-type to self-propelled sprayers has introduced new variables to consider. However, the basics of spraying have remained the same. It is necessary to use sprays that achieve both good coverage and good drift control, and these sprays need to work with sometimes complex tank mixes over a range of weather conditions. This is especially important for pulse growers, for whom the efficacy of pesticides is particularly important due to the low competitive ability of pulse crops in the early stages of development.

Spray applicators need to consider several spray inputs that interact with each other. This resource will first cover basic information on spraying—as a starting point for both new and experienced applicators. Second, it will provide more specific information of interest to pulse growers, with reference to crops and pesticides they may encounter.

Nozzle Tasks

The spray nozzle has three very important tasks. First, it meters the liquid flow rate of the sprayer. Spray tips come in a variety of fixed sizes, where flow rates are identified on nozzles by numbers and colours that indicate their nominal flow rate in US gallons per minute (gpm) at 40 pound per square inch (psi), spraying water. They help identify nozzles from which the identifying number has rubbed off, they are colour coded. All manufacturers of boom sprayer nozzles conform to this sizing standard.

The second nozzle task is atomization. The metered liquid needs to be divided into enough small droplets so that the liquid can “cover” the intended target. Usually, this means creating between 50 to 100 droplets per square centimetre.

The third task is for the nozzle to distribute these droplets over a specific distance determined by the spacing of the nozzle along a boom or by the band width the deposit creates

Nozzle design and operating pressure are the key parts of making this work. In Saskatchewan agriculture, tapered flat fan nozzles are primarily used to generate the spray. These nozzles deposit most of their flow under the nozzle, diminishing towards the edges and requiring the proper overlap to create an even distribution. Modern nozzles produce medium to very coarse sprays on average, which satisfy the need for both acceptable drift control and coverage.

Nozzle Sizing

Nozzles must be sized according to the nozzle spacing, the desired water volume, and the intended travel speed to function at the optimal spray pressure, and in the case of PWM, duty cycle.

A simple formula used to relate all these factors is below, where w is the boom’s nozzle spacing in inches:

![gpm = [gallons per acre (gpa) x miles per hour (mph) x w] / [5940 x (duty cycle/1000}](https://saskpulse.com/wp-content/uploads/2023/05/formula1-1024x84.png)

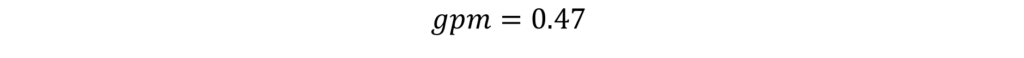

This formula can be used to determine the individual nozzle flow required to make an application. For example, an application of 10 US gpa is to be made at 14 mph using a boom with a nozzle spacing of 20 inches. The boom is not PWM equipped, therefore the duty cycle can be taken as 100%.

![gpm = (10 x 14 x 20) / [5940 x (100/100)]](https://saskpulse.com/wp-content/uploads/2023/05/formula2-1024x92.png)

We know from the standard nozzle charts that a 04-sized nozzle (red) delivers 0.4 gpm at 40 psi. This nozzle could deliver 0.47 gpm but at a higher pressure. A 05-sized nozzle (brown) delivers 0.5 gpm at 40 psi and would require less than 40 psi.

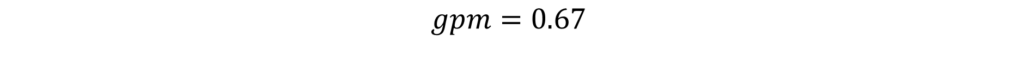

A PWM-equipped sprayer would size nozzles for a duty cycle of 70% as a starting point.

![gpm = (10 x 14 x 20) / [5940 x (70/100)]](https://saskpulse.com/wp-content/uploads/2023/05/formula4-1024x92.png)

For the above example, the formula now requires a higher flow rate.

From this result, we know the nozzle size would need to be at least 0.6 US gpm. The next size, the 08 nozzle, would likely be too large. Unlike the conventional sprayer system, the PWM system would not need precise pressure to deliver this flow rate. The applicator chooses the pressure according to the spray quality they need for the job, and the duty cycle adjusts slightly to ensure the correct flow rate is achieved. The final duty cycle should be between 60 and 80% to ensure proper operation of the system.

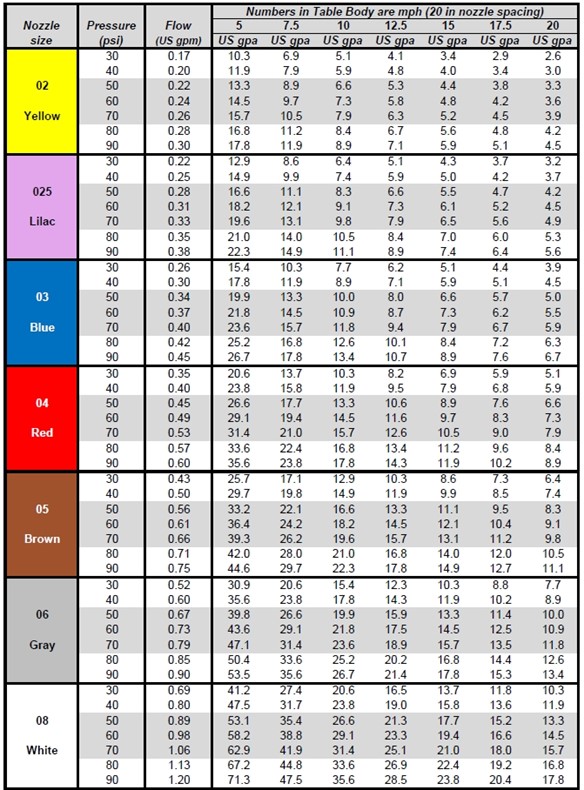

An easy way to put all these pieces together is to use a spray calibration chart. These are available in any sprayer catalogue, or on Sprayers101.com.

In this example, use the chart to identify the desired spray volume, listed along the top row. Search down the 10 gpa column looking for the target 14 mph speed, which will correspond to the 0.47 gpm flow rate solved for, above, with the formula. Once a number near the target value is found, move back across to the nozzle size and spray pressure at which the conditions were met. Here, the 04 nozzle would operate at approximately 70 psi and the 05 nozzle at about 35 psi.

For the PWM example, there are two choices to calculate a nozzle recommendation for the flow rate of 0.67 gpm. First, move down the flow rate column, looking for 0.67 gpm. The 06 nozzle at 50 psi is very close. The 08 nozzle at 30 psi might also work. Alternatively, artificially boost the travel speed to 20 mph (14 mph/0.7 duty cycle). Note that the solution is about the same.

To decide, consider two additional pieces of information. What is the pressure at which the nozzle produces the desired spray quality (droplet size)? And what is the pressure range of the nozzle? These aspects are covered in Figure 3.

Boom Height

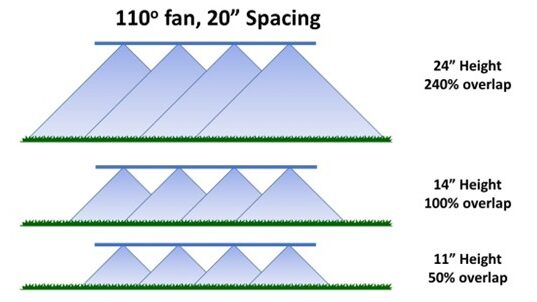

Spray boom height is important for three reasons. First, a specific nozzle fan angle and spacing requires a minimum boom height to achieve the minimum overlap for a uniform deposit pattern.

Spray patterns should have at minimum a double (100%) overlap, more for PWM-equipped sprayers. This means that every area under the boom should receive spray from two nozzles. Another way to say this is that the spray pattern should be twice the nozzle spacing. The general rule of thumb is that for 20-inch nozzle spacing, the boom height should be at least 20 inches for 110-degree nozzles. There is no penalty for higher boom heights except that drift and variability may increase. But too low a boom can create a striped pattern, particularly for coarser sprays where the larger droplets do not redistribute easily.

Second, the boom height is a powerful determinant of spray drift potential. The rule of thumb is that doubling the boom height from 20 to 40 inches above ground doubles the drift potential in a wind.

Finally, the performance of an angled spray, usually designed to provide a specific droplet trajectory for improved canopy interception, is highly dependent on the distance the spray has to travel. Longer distances that allow the droplets to succumb to headwinds, for example, diminish the angled direction of droplets in these sprays and approach the performance of a single nozzle.

Travel Speed

One of the most significant changes that the move to self-propelled sprayers brought to spray application was a significant increase in travel speed. Whereas pull-type sprayers travelled between five and eight mph in the 1980s, self-propelled sprayers are capable of two to three times that speed. The increase in speed and weight has five significant consequences:

- Nozzle sizes have increased to permit greater flow rates. This has made it more difficult to achieve good coverage with low water volumes.

- Boom heights are higher to allow for greater boom sway. The larger droplet travelling distance has increased drift potential.

- Travel speed range has increased due to terrain or power constraints. This has necessitated nozzles that can operate well under a variety of spray pressures and encouraged the move to PWM systems.

- Spray turbulence caused by the physical structure of the sprayer has increased (Figure 6). Greater turbulence has reduced the uniformity of spray deposits, resulting in the potential for regions of lower control, such as behind-wheel tracks.

- Overall sprayer weight has increased, requiring larger wheels to maintain floatation. Larger wheels displace more air, creating a bigger impact on deposition in their wake.

Spray Pressure

Spray pressure is the single most important operating parameter for a hydraulic nozzle. Pressure atomizes the spray, and a certain minimum pressure is needed for the pattern to form fully so that it achieves proper distribution and overlap. For most modern low-drift nozzles, a minimum pressure of 30 psi is a good rule of thumb. Higher pressure creates a finer spray for all nozzles, and a reasonable maximum is about 90 psi. Therefore, 50 to 70 psi is a good intermediate pressure to operate at.

Spray pressure is very sensitive to travel speed. Being in the middle of the operating range allows for pressure to decrease when slowing down and increase when speeding up. An air-induced nozzle or pre-orifice low-drift nozzle will still produce a low-drift spray at those pressures. Even for PWM sprayers, the middle of the range has value so that the operator can adjust spray quality up or down to suit conditions.

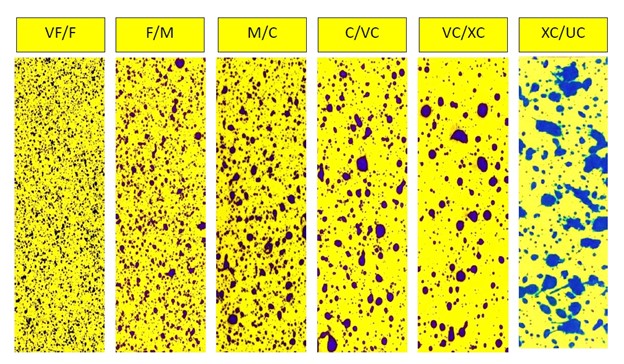

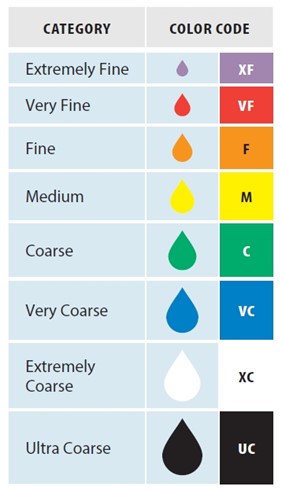

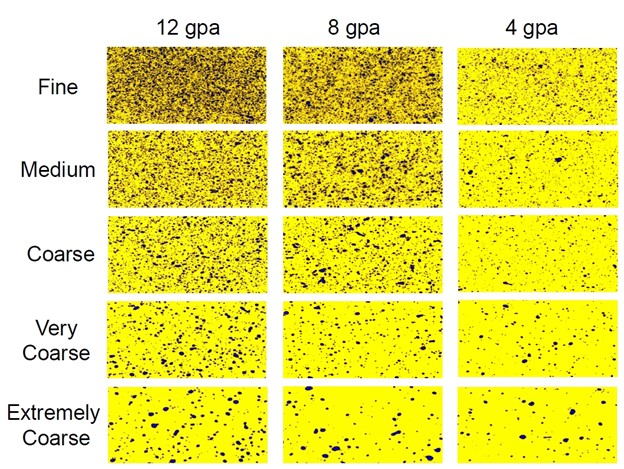

Spray Quality

Spray quality is a term that describes the droplet size spectrum of a particular spray. All hydraulic nozzles produce a wide variety of droplet sizes, ranging from about 5 µm to 1000 µm or even 2000 µm for the coarser sprays. The volumetric distribution of these droplets determines their spray quality, as compared to specific reference nozzles specified by international standards. Most agricultural nozzles produce medium to very coarse sprays, and these in turn provide adequate coverage at a minimum of five to ten US gpa.

Spray quality is published in manufacturer catalogues and in online product profiles. Applicators need to pay attention to the version of the standard which was used to create the classification. Since 2018, new standards have been available (American Society of Agricultural and Biological Engineers [ASABE] S572.3 and ISO 25358) which classify the same sprays as finer than under the older standards (S572,1 and S572.2). As of 2023, only TeeJet is reporting its spray qualities under the new S572.3 standard.

Coarser sprays reduce drift but also contain fewer droplets, reducing coverage density. The larger droplets they contain may be difficult for smaller targets to intercept and retain. Emerging weeds at the cotyledon or 1-leaf stage, perhaps in a burnoff spray, are examples where some small droplets will be needed to hit the targets. In addition, difficult-to-wet plant surfaces are not able to dissipate the incoming energy of larger droplets as well as easy-to-wet plants, possibly increasing rebound and reducing overall control. Fortunately, most pulse crops are intermediate in their wettability, making retention of the larger droplets a non-issue for the most part.

Finer sprays have better retention than coarser sprays on some plant surfaces and make better use of lower water volumes, but they suffer from much higher evaporation rates and greater drift potential which limits their practical utility under adverse weather conditions. Considering that fungicide application and desiccation of pulse crops can occur in the hottest part of the summer, caution is advised when using finer sprays at that time of the growing season.

Water Volume

The amount of coverage achievable with a spray is a simple mathematical relationship between water volume and spray quality. It is intuitive that finer sprays produce more droplets from any given amount of water, and that larger water volumes permit the use of coarser sprays. In general terms, most products (except for glyphosate) benefit from the use of higher water volumes. Pesticide performance consistency, particularly under challenging conditions such as denser canopies, windier spray days, and hotter temperatures, is higher with more water and slightly coarser sprays.

Glyphosate is a special case that has been shown to improve performance with lower water volumes and coarser droplets. Lower volumes increase the concentration of formulated surfactants in the mix and decrease the adverse impact of hard water cations such as magnesium and calcium. However, glyphosate is increasingly being tank-mixed with contact products such as Group 6 and 14, and these products require higher water volumes for best performance. As a result, the use of water conditioners has been encouraged with higher glyphosate water volumes to maintain good efficacy.

Table 1. Recommended spray volumes and spray qualities for a variety of modes of action in pulse crops. Note that higher water volumes may allow for coarser sprays.

| Mode of Action Group | Example Active Ingredients | Water Volume (US gpa) | Spray Quality | Wilger Tip Wizard VMD (µm) (wilger.net) |

|---|---|---|---|---|

| 1 | clethodim, quizalofop, sethoxydim | 7–10 | Medium to coarse | 220–400 |

| 2 (broadleaf weeds) | imazamox, imazethapyr thifensulfuron | 6–10 | Coarse to very coarse | 270–460 |

| 2 (grassy weeds) | imazamox, imazethapyr | 7–10 | Medium to coarse | 220–400 |

| 4 | MCPB | 6–10 | Coarse to very coarse | 270–460 |

| 5 | metribuzin | 8–10 | Medium to coarse | 220–400 |

| 6 | bentazon | 7–10 | Medium to coarse | 220–400 |

| 9 | glyphosate | 3–5 | Coarse to very coarse | 270–460 |

| 14 | carfentrazone, saflufenacil, flumioxazin | 8–10 | Medium to coarse | 220–400 |

| 15 | pyroxasulfone | 10 | Coarse to very coarse | 270–460 |

| 22 | diquat | 10–15 | Medium to coarse | 220–400 |

Common Nozzle Options

As we can see from Table 1, the ideal spray quality for pulse growers will be medium to coarse for contact sprays or grassy weeds, and coarse to very coarse for systemic products and broadleaf targets. This applies primarily to herbicides. For fungicides, research has shown fungicides to be relatively insensitive to spray quality. For conventional sprayers, recommended nozzles are manufactured (in alphabetical order) by Arag (CFA), Billericay (Air Bubble Jet), Agrotop (AirMix), Hypro (GuardianAIR or Low Drift Air, LDA, for John Deere), Lechler (IDK), TeeJet (AIXR), and Wilger (SR, MR).

Table 2: Nozzles available for general application of pesticides.

| Manufacturer | Model | Approved for PWM | Spray Quality | |||||

| F | M | C | VC | XC | UC | |||

| Agrotop | AirMix (AM) | No | ✔ | ✔ | ✔ | |||

| TurboDrop XL | No | ✔ | ✔ | ✔ | ||||

| Blended Pulse | Yes | ✔ | ✔ | ✔ | ||||

| Soft Drop | Yes | ✔ | ✔ | |||||

| Arag | Compact Fan Air (CFA) | No | ✔ | ✔ | ✔ | |||

| Compact Fan Low Drift (CFLD) | Yes | ✔ | ✔ | ✔ | ||||

| Billericay | Air Bubble Jet | No | ✔ | ✔ | ||||

| EasyJet | Yes | ✔ | ✔ | |||||

| Hypro | GuardianAIR (GA) | No | ✔ | ✔ | ✔ | |||

| Ultra Low Drift (ULD) | No | ✔ | ✔ | ✔ | ||||

| 3D | Yes | ✔ | ✔ | ✔ | ||||

| Guardian | Yes | ✔ | ✔ | ✔ | ||||

| Lechler | IDK | No | ✔ | ✔ | ✔ | |||

| ID3 | No | ✔ | ✔ | ✔ | ||||

| TeeJet | Air Induced Ext. Range (AIXR) | No | ✔ | ✔ | ✔ | |||

| Air Induction (AI) | No | ✔ | ✔ | ✔ | ||||

| Turbo TeeJet (TT) | Yes | ✔ | ✔ | ✔ | ✔ | |||

| TurboTeeJet Induction (TTI) | Yes | ✔ | ✔ | |||||

| Wilger | ER | Yes | ✔ | ✔ | ||||

| SR | Yes | ✔ | ✔ | |||||

| MR | Yes | ✔ | ✔ | |||||

| DR | Yes | ✔ | ✔ | |||||

Aerial vs Ground Application

Aerial application is an important part of the crop protection industry. Both fixed- and rotary-wing aircraft have the advantage of very high productivity, being able to cover larger areas in any given day. This is important when time is of the essence to treat disease or insect pests in pulse crops. Aircraft also have the advantage of not making contact with the crop or ground, an important consideration for two reasons: (a) later season sprays where the canopy is often tall and significant crop damage can occur from wheels (b) harvesting with a flex header can be difficult when navigating through wheel tracks or ruts. It has also been suggested that wheels can spread spores of diseases like Ascochyta blight in chickpea, for example.

Like ground sprayers, aircraft have grown in size and capacity in recent years. Whereas the common Cessna AgTruck, Piper Pawnee, or AgCat had hopper capacities between 200 and 300 US gallons and flew at between 100 and 120 mph air speed, current aircraft are about twice as large. The Air Tractor 502B and 602, for example, have hoppers of 500 and 600 US gallons, respectively and their turbine engines allow them to spray at 140 mph. With the wider wings, the swath width also grew, to about 70 to 75 feet per swath, depending on the application volume. An aircraft’s key advantage is productivity, allowing the spray to be applied at the right time. This is particularly important in disease control.

Aerial labels for fungicides typically require less water than ground labels, owing due to the practical limitations in tank size and the proximity of the landing strip. On reviewing fungicide labels for pulse crops, all aerial water volumes were found to be at least 4.3 US gpa, with the majority being 5.3 US gpa. For the same product, ground application was most commonly 10.7 US gpa, but in some cases, higher volumes were required. Aerial applicators often wish to apply less water than the label requires. A customer needs to discuss these issues with the aerial operator to make sure expectations can be met.

When comparing ground and aerial applications, these compare favourably when label volumes are applied. When looking at Ascochyta control in chickpeas, applying fungicide twice (Lance®, then Headline®) increased seed yield from 13 bushels per acre (bu/ ac) in the untreated to 33 bu/ac in the treated. Yields from ground application were 1.7 bu/ac higher than aerial, this difference was not statistically significant. Yield loss from tracks, adjusted for 90’ boom widths, was 1.6 bu/ac.

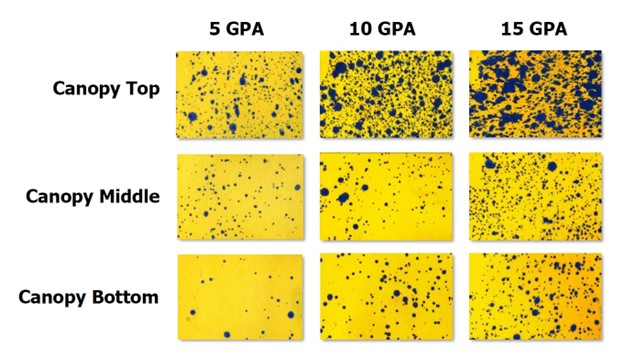

Canopy Penetration

While the minimum water volume values are useful guidance, additional comments on product labels call for “thorough and uniform coverage”. Again, the combination of water volume and droplet size will drive coverage, but additional considerations are awareness of the disease cycle and leaf area index (LAI). LAI is defined as the amount of total leaf area per unit of ground area, and increases over the growing season, peaking near the time of fungicide application. Although it is difficult to measure LAI, it is possible to judge it visually. First, understand the origin of the disease and the mode of action of the fungicide. If the lower canopy needs to be treated, for example anthracnose in lentils, the canopy can be viewed from above. If it is possible to see lower parts of the canopy, or the ground itself, then lower water volumes can achieve satisfactory canopy penetration and coverage. If these are obscured by plant material, more water is required. The denser the canopy, the more water is needed.

Surprisingly, this effect is largely independent of spray quality. Tests have shown that finer sprays do, in fact, penetrate dense broadleaf canopies such as soybeans more effectively than coarser sprays. But larger water volumes, combined with slower travel speeds, can improve canopy penetration to a greater degree.

Pulse Width Modulation

Most new sprayers are equipped with a form of PWM. This system uses electric solenoids to control the flow rate rather than spray pressure. PWM solenoids alternately open and close at a fixed frequency, commonly 15 or 20 Hz. The proportion of time that a solenoid is open is called the duty cycle. A 100% duty cycle means the nozzle is flowing at full capacity. A 50% duty cycle means the nozzle is in the open position 50% of the time and closed the remaining time. The duty cycle is almost linearly related to the average flow rate, resulting in the ability to control flow by a factor of about 5:1, meaning a duty cycle of 20 to 100%. This is very useful, as it allows changes in travel speed that do not result in changes in spray pressure. It also allows turn compensation, the ability of the spray boom to deliver uniform rates along the entire boom when the sprayer is turning. PWM systems require nozzles that function properly when frequently shut off and turned back on, air-induction nozzles commonly do not qualify. In addition, PWM systems require nozzles that produce about 30 to 40 % more flow than those in conventional systems, forcing the PWM valves to operate at 60 to 70% duty cycle on average. This optimizes the system’s performance.

Table 3: Summary of application volumes, spray qualities, and buffer zones for common fungicides used in pulse crops in Saskatchewan

| Product | Aerial | Ground | ||||

| Volume (US gpa) | Spray Quality | Buffer Zone | Volume (US gpa) | Spray Quality | Buffer Zone | |

| Acapela™ | 5.3 | medium | yes | 11.8 | medium | yes |

| Allegro® 500F | 4.8 | medium | yes | 21.4 | medium | yes |

| azoxystrobin | 4.8 | medium | yes | 21.4 | medium | yes |

| boscalid | 4.3 | medium | yes | 10.7 | medium | yes |

| chlorothalonil | 5.3 | medium | yes | 10.7 | medium | yes |

| Cotegra® | 5.3 | medium | yes | 10.7 | medium | yes |

| Delaro® | 5.3 | medium | yes | 10.7 | medium | yes |

| Dyax™ | 5.3 | medium | yes | 10.7 | medium | yes |

| Elatus® | 4.8 | medium | yes | 10.7 | medium | yes |

| Kenja® | n/a | n/a | n/a | 5.3–10.7 | medium | yes |

| mancozeb | 5.3 | medium | yes | 5.3 | medium | yes |

| Miravis® Pro | 5.3 | medium | yes | 10.7 | fine | yes |

| Phostrol® | 5.3 | medium | yes | 10.7 | medium | yes |

| Priaxor® | 5.3 | medium | yes | 10.7 | medium | yes |

| Proline® Gold | 5.3 | medium | yes | 10.7 | medium | yes |

| propiconazole | 4.3 | medium | yes | 21.4 | medium | yes |

| Propulse™ | 5.3 | medium | yes | 10.7 | medium | yes |

| prothioconazole | 5.3 | medium | yes | 10.7 | medium | yes |

| pyraclostrobin | 5.3 | medium | yes | 10.7 | medium | yes |

| Quash® | 5.3 | medium | yes | 21.4 | medium | yes |

| Quilt® | 4.8 | medium | n/a | 10.7 | medium | n/a |

The Ideal Application

In-crop herbicides should be applied at no less than 10 US gpa in pulse crops. The more dilute concentration makes for greater crop safety, an important issue for more sensitive pulse crops. Higher water volumes also allow for the use of “coarse” sprays that prevent drift, or looked at another way, an opportunity to spray in higher winds without increasing drift risk. In addition, larger droplets take more time to evaporate, and this assists in the uptake of the spray by weeds. All these factors are valuable when considering productivity and efficacy.

For late-season application of fungicides or desiccants, the density of the canopy will determine the correct water volume, which will almost certainly need to be higher than 10 US gpa. Higher volumes are needed especially when needing to reach deeper into the canopy, and slower travel speeds contribute to achieving this goal. Make an initial assessment by estimating the density visually. The less ground that is visible, the more water will be beneficial. The use of water-sensitive paper is an excellent way to see the spray’s deposition, and to keep a record of the application should a problem arise.

Sprays should be applied on sunny days whenever possible for pest pesticide performance. The presence of some wind can be mitigated with coarser sprays and higher volumes, and this is preferred to spraying at night when inversions are common and uncontrollable drift may occur.

Farming has never been more complex. Producers need to be experts in a lot of different areas, and each of these areas is also becoming more complex, and spraying is no exception. We hope this application guide has been of some value in guiding the way you apply pesticides.

If more detail is sought, consider using the free website Sprayers101. com. It is written for producers and agronomists and covers a wide variety of aspects in depth.

Happy spraying!

Tom Wolf is a professional agrologist with Agrimetrix Research & Training.