By Tom Wolf, Agrimetrix Research & Training

Introduction

There are many ways to optimize spray applications, including the use of adjuvants. Understanding how adjuvants work with pesticide applications is a leading area of confusion for many Saskatchewan producers. Several adjuvant specialty companies have recently increased their portfolio in Western Canada, and producers areasking questions about the value of using these products. Adjuvants are particularly important when spraying pulse crops. They can improve pesticide performance, which is important for crops like peas or lentils that are slow to establish and require efficacious herbicides to help prevent yield loss early in their development. Adjuvants can also help maintain good pesticide performance indirectly by, for example, ameliorating antagonism from hard water and helping reduce spray drift. This resource will explain what adjuvants are used in pulse production, how they work, and how to avoid pitfalls when using them.

Adjuvants

Adjuvants are defined as “any substance in an herbicide formulation or added to the spray tank to modify the biological activity or application characteristics”. It is a broad umbrella term much like the word “pesticide”, which can contain herbicides, fungicides, insecticides, rodenticides, etc. Adjuvants can be broadly classified into three categories: activators, spray modifiers, and utility modifiers (Table 1). In Canada, activators are the most used adjuvants, as this group contains surfactants and crop oil concentrates. Because activators are critical to the performance of a pesticide product, they are either included in the formulation itself or are identified on the product label by name.

Table 1. Adjuvant categories used in Canada

| Adjuvant Type | Examples | Purpose |

|---|---|---|

| Activators | Surfactants | Increased droplet spread; Improved contact |

| Crop Oils; Crop Oil Concentrates; Methylated Seed Oils | Slower evaporation; Enhanced uptake | |

| Utility Modifiers | pH Adjusters; Anti-foamers; Water Conditioners; Drift Control Agents | Enhance solubility; Manage excessive foaming; Lower hardness; Eliminate fine droplets |

Activators

Virtually all pesticides utilize surfactants to enhance either storage stability, mixing, or efficacy. In most cases, surfactants are part of the formulated product and are already in the jug. This is the case for glyphosate products and other solution formulations such as Liberty®. Adding surfactants to the formulation is not always practical, however. When the pesticide formulation contains too little or no surfactant on its own, or when application rates or volumes dilute the surfactant in the formulation to such a degree that additional surfactant is needed, the applicator must add surfactants to spray solution during mixing and loading. Surfactants can be very specific in their effects, and it is important to follow label directions to avoid making mistakes (Table 2, next page).

Many Group 2 products call for surfactants to be added during mixing. Group 2 products, while most commonly applied in pulse crops, generally have very low use rates and when they are dry formulations, the advantage of easier handling would be undone with an inclusive formulation. As a result, these products are co-packed with an activator like Merge or call for a generic non-ionic surfactant to be added.

Crop oil concentrates (COCs) are vegetable or petroleum oils whose primary function is to enhance the uptake of an herbicide into the plant. COCs contain special surfactants called emulsifiers that help the oil mix with water. Many Group 1 herbicides such as Assure® II (quizalofop) or Centurion® (clethodim) are mixed with crop oil concentrates which are specifically designed for that herbicide and are packaged together. A variant of the COC is methylated seed oils (MSOs). These are manufactured by reacting vegetable oils with methanol, which creates an activator with good spreading and uptake characteristics. MSOs are more versatile than crop oils and are often used with Group 1 products like quizalofop or sethoxydim (Poast® Ultra), Group 2 products such as Odyssey® or Pursuit®, and even Group 14 products like Heat® (saflufenacil).

Activators as a group are very specific in their activity. Activators that work well with one herbicide may not work at all with another, or they may even reduce performance. For example, crop oil concentrates do not work with glyphosate and should not be used with it. The product label remains the best guide for using activators. If the activator named on the product label is not included in the package, obtain it from the retailer at the time of purchase.

Table 2. A summary of pulse crop adjuvant registrations with herbicides in Western Canada

| Pesticide | Adjuvant Name | Adjuvant Type | Composition |

|---|---|---|---|

| diquat glyphosate imazethapyr | Agral 90® IPCO Agsurf® Original MPOWER Icon | Non-ionic surfactant | 92% nonylphenoxy polyethoxy ethanol |

| 92% alcohol ethoxylate | |||

| Basagran® (bentazon) Pinnacle® (thifensulfuron) | Citowett® Plus Super Spreader | Non-ionic surfactant | 50% octylphenoxypolyethoxy ethanol |

| Glyphosate | Companion | Non-ionic surfactant | 70% octylphenoxypolyethoxy-(9)- ethanol |

| diquat Folicur® 432 (tebuconazole) glyphosate imazethapyr Pinnacle® (thifensulfuron) Reflex® (fomesafen) Valtera™ (flumioxazin) | Enhance Nufarm Enhance® ADAMA 80 | Non-ionic surfactant | 80% triglyceride ethoxylate 10 POE |

| Assure® (quizalofop) Pursuit® (imazethapyr) | HiActivate® | Non-ionic surfactant | 900 g/L alkylarylpolyoxyethylene glycols, free fatty acids & isopropyl alcohol |

| diquat glyphosate quizalofop | LI 700® | Non-ionic surfactant, Water Modifier, Drift Retardant | 80% surfactant blend |

| Aim® (carfentrazone) diquat glyphosate imazethapyr quizalofop | IPCO Surfactant NI | Non-ionic surfactant, Water Modifier, Drift Retardant | 100% surfactant blend |

| Heat® WG, LQ (saflufenacil) Odyssey® (imazamox, imazethapyr) Odyssey® Ultra (imazamox, imazethapyr, sethoxydim) Poast® Ultra (sethoxydim) quizalofop Solo® (imazamox) | Merge MPOWER® Assassin® Surjet™ | Surfactant blend | 50% surfactant blend, 50% solvent (petroleum hydrocarbons) |

| clethodim | Amigo® X-Act CO-OP® Patron IPCO X-Surf® MPOWER® Empire Surf-Act® | Anionic surfactant | 30% phosphate ester surfactant |

| clethodim quizalofop | Journey® HSOC | Methylated Seed Oil | 50% methylated seed oil of soybean |

| Heat® (saflufenacil) imazamox imazamox+imazethapyr glyphosate Valtera® (flumioxazin) quizalofop | IPCO MSO Adjuvant | Methylated Seed Oil | 100% surfactant blend |

| Assure® II (quizalofop) Odyssey® (imazamox) Pursuit® (imazethapyr) Reflex® (fomesafen) | Liberate® | Methylated Seed Oil, Water Modifier, Drift Retardant, Sticker | 100% lecithin, methyl esters of fatty acids and alcohol ethoxylate |

| imazethapyr Odyssey® (imazamox) Poast® Ultra (sethoxydim) quizalofop (Contender) | MSO® Concentrate with Leci-Tech® IPCO Contender® MSO® Adjuvant with Leci-Tech® | Methylated Seed Oil, Drift Retardant | 70% methylated seed oil of soybean |

| Basagra®n (bentazon) Ultra Blazer® (acifluorfen) quizalofop (Contender, Yuma® GL) | Assist® Oil Concentrate CropOil 83/17 XA Oil Concentrate Score® Chem Spray® | Crop Oil Concentrate | 83% paraffin based mineral oil, 17% surfactant blend |

| quizalofop | Sure-Mix™ Surfactant | Crop Oil Concentrate | 60% paraffinic petroleum oil 40% surfactant blend |

Utility Modifiers

Most utility modifiers usually do not have efficacy-enhancing properties, rather they enable the active ingredient to perform as expected based on the label description. Some properties may be mentioned on the product label to improve some aspects of the behaviour of pesticides during mixing, cleaning, or application. Among the utility modifiers are pH adjusters, defoamers, water conditioners, and drift control agents. Most of these products are added when conditions require it, such as when water hardness is high, foaming is excessive, or drift is problematic.

pH adjusters are sometimes used to enhance the solubility of an active ingredient or to enhance active ingredient absorption. Pesticides can be very sensitive to pH—some require low pH to dissolve; others require high pH. It is important to understand the requirements of the tank mix before adjusting pH.

The herbicides that are most sensitive to pH are the Group 2 products. Of these, only two different subgroups are used in pulse crops. The first is imidazolinone, or “imi”, originally manufactured by BASF. Products include Odyssey®, Pursuit®, Ares®, and Viper®. These products dissolve water with a range of pH values but prefer lower pH. The other group is the sulfonylureas (SU), with Pinnacle® (thifensulfuron) registered in soybeans. It requires high pH for proper solubility and should not be acidified. The consequence of poor solubility may include poor weed control and increased risk of tank and plumbing residues.

Drift control agents, used to decrease to volume of driftable small droplets in sprays, are mandated for some applications in the United States (U.S.) and are becoming popular in Canada. Example products are InterLock® and MasterLock®, produced by Winfield United, and Valid® and LI 700®, produced by Loveland Products (Nutrien). These are generally compatible with pesticides, and their key feature is the reduction of driftable, fine droplets by roughly 50%, without significantly adding to the larger droplets. As a result, they make better use of spray volume. It is important to note that the type of nozzle and the tank mix constituents affect the effectiveness of low- drift adjuvants, and results may vary.

It is also important to note that some of these products make multiple claims about their activity, and in Canada, this reduces the scope of their legal use. Both LI 700® and MasterLock® are advertised as surfactants as well as low-drift adjuvants, whereas Valid® is described as an anti-foamer and low-drift adjuvant, and InterLock® is described as a low-drift adjuvant and deposition and penetrating aid. The products that claim to be activators must support those claims with data, and that limits their legal use.

Again, the adjuvant label is your guide. For example, MasterLock® contains a non-ionic surfactant, and in Canada, its use is limited to three fungicides (Proline®, Miravis® Bold, and Miravis® Ace) in canola and wheat. This limitation is not mentioned on the U.S. label, where efficacy data are not needed for registration. Its sister product, InterLock®, does not contain non-ionic surfactant (NIS) and there is no crop or product restriction to its use in Canada.

LI 700® is another example where the label clearly identifies permitted tank mixes. For pulse crops, LI 700® is permitted with glyphosate in pre-seed use, or with Reglone® for the desiccation of edible beans, soybeans, and lentils, but not peas. There is no such herbicide or crop restriction with its sister product Valid®, which has no advertised activator properties and is sold as a low-drift adjuvant and defoamer.

Why the Confusion?

One of the reasons people are confused about adjuvants is because they are always described with positive attributes such as wetter, spreader, deposition aid, conditioner, etc. What is not mentioned is that these attributes have positive effects in some cases, and negative effects in others. Any given product can increase, decrease, or have no effect on pesticide performance.

An example of the specificity of adjuvants is organosilicone, a group of activators with superior spreading activity. While enhanced spreading and wetting are positive attributes, research has shown that too much spreading can result in reduced uptake, in some cases leading to runoff and spreading a droplet out over a leaf also increases its rate of evaporation. All these effects can ultimately reduce efficacy.

Regulation of Adjuvants

Canada is one of the few countries where adjuvant registrations require performance data. To be registered, the Pest Management Regulatory Agency (PMRA) reviews efficacy data for activators or other performance indicators for utility modifiers. The most common class of activators is NIS, which is frequently mentioned on product labels. There are a large number of NIS products, and these can be considered generic unless the product makes additional special performance claims, such as LI 700®.

A new activator adjuvant needs to be tested with the pesticide for which it is recommended. Usually, performance data of that activator are provided at the time of registration, based on field trials. Reviewers at PMRA want to see evidence that the activator improves performance, allowing a reduction of the registered label product rate. For that reason, product labels rarely mention more than one activator. As a rule, if a pesticide rate can be reduced with an activator, the registrant for that pesticide will register its own proprietary activator and require its use on the label. There is little incentive to add other activators.

If an adjuvant manufacturer wishes to register an activator with a pesticide, they would need to provide efficacy data supporting the claimed benefits of their product. Due to the associated expense, we see very few third-party activators registered in Canada which makes life simpler for growers and spray applicators. The product label does, indeed, provide nearly all the instructions needed to maximize product performance. It is in the interests of the original registrant of the pesticide to maximize its performance with in-house formulation or recommended additives. We usually see relatively little efficacy left on the table for the after-market to take advantage of.

Utility modifiers, however, are easier to register in Canada. A registration request for a drift reducer adjuvant simply needs to show that drift-prone droplets are reduced with the addition of the adjuvant. A request for a pH adjuster needs to show it can alter the pH as advertised. As a result, we are seeing a larger number of utility modifiers in Canada.

Surfactants

Surfactants are such an important class of adjuvants that it is worthwhile to explore how they work in more detail. They are a class of activators that are primarily known for their ability to reduce surface tension of a spray solution. Water by itself has a high surface tension because water molecules are highly polar and are attracted to each other. They form bonds and become closely packed, and this cohesion causes droplets to form into a tight spherical shape.

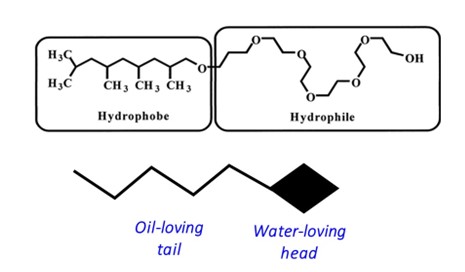

Surfactants are special molecules that contain properties of both water and oil. One end of the molecule is oil-loving (lipophilic), and the other is water-loving (hydrophilic) (Figure 1). When added to water, they mix among the water molecules and replace the very cohesive bonds among water molecules with less cohesive bonds between water and surfactant. Surface tension is reduced, and the droplet is able to relax and interact with other surfaces.

If a droplet comes in contact with a waxy leaf surface, the surfactant can form a bridge between the water and the wax. The oil-loving parts of the surfactants interact with the wax, and the water-loving parts interact with the water in the solution, giving the droplet better contact with the leaf surface. The surfactant increases the likelihood that the spray droplet will be retained by the leaf and spread on it.

Surfactants can also dissolve cuticles, helping the active ingredient more readily enter the leaf surface. Some surfactants, or surfactant concentrations, can dissolve plant membranes, which can enhance herbicidal activity. For translocated pesticides such as the Group

2 products (Odyssey®, Solo®, Ares®), Group 1 products (Assure®, Centurion®, Poast®), and Group 9 products (glyphosate), however, a living cell is required for movement out of the treated area to

the growing point. A surfactant or pesticide tank mix partner that damages membranes could reduce translocation, with a resulting drop in pesticide performance. Sprays that create a burn on the leaf, creating dead tissue where they contacted the plant, likely did so because they destroyed the underlying plant tissue. This could be contact products like Basagran® or Sencor®, but also foliar fertilizers or water-conditioning adjuvants like ammonium sulphate (AMS) or urea ammonium nitrate (UAN).

Atomization

When spray liquid is pressurized through a nozzle on the sprayer, it forms a thin sheet that eventually becomes unstable and forms droplets. This conversion from a bulk liquid to droplets is called atomization, and it is one of the most critical components of a spray application. The resulting droplet size determines coverage and drift potential, exposure to evaporation, and overall deposition behaviour.

The use of adjuvants can have strong impacts on the physiochemical properties of a spray solution, with consequences for spray atomization. In general, lower surface tensions and viscosities create finer sprays, whereas oily products tend to suppress the formation of finer droplets. Experienced applicators frequently notice how some pesticide products seem to atomize finer than others, and this has to do with all the components in the spray mix.

An important class of utility modifiers capitalizes on the property of oily formulations to suppress the formation of finer droplets. Products such as InterLock®, Valid®, and LI 700®, as well as generic versions of these products, can reduce driftable spray droplets (those less than 100 to 150 µm in diameter) by about 50%, depending on the nozzle and product used. This is an important feature and has proven useful because these products, unlike low-drift nozzles, do not increase the formation of larger droplets that use up water without adding coverage.

Sourced from Dr. Paul Miller, Silsoe Research Institute

Spray Retention

Western Canadian weeds comprise many different surface properties. Most grassy weeds, except for barnyard grass, are difficult-to-wet, whereas broadleaf weeds are usually easy-to-wet, but with significant exceptions. Kochia, lambsquarters, and volunteer canola are key examples of broadleaf weeds in pulse production that are difficult- to-wet. A leaf’s wetting ability is related to the microscopic form of its surface. Crystalline waxes have rough surfaces that can trap air, preventing a droplet from making direct contact. Some leaves have more water-hating wax types than others. Others still have small hairs that form a barrier between the drop and the leaf surface.

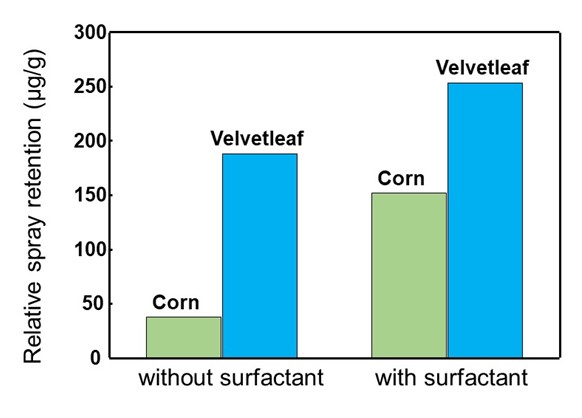

Generally, weeds that are difficult-to-wet benefit more from surfactants than those that are easy-to-wet. Droplet bounce studies have shown that both large and small water droplets could be retained by pigweed leaves (easy-to-wet), whereas no size of water droplets could be retained by foxtail leaves (difficult-to-wet). When surfactant was added to the spray solution, small droplets could be retained by foxtail, although larger droplets still tended to bounce off. In spray retention studies, the impact of leaf type could be demonstrated by applying a water spray and a surfactant-containing spray to corn (difficult-to-wet) and velvetleaf (easy-to-wet). Surfactant greatly enhanced retention in corn, but only had minor effects on velvetleaf (Figure 5). It is therefore important to understand the nature of the weed target being sprayed to predict the impact of adding a surfactant.

Wettability can change with leaf age and the growing environment. A simple test can be done with a spray bottle of water. Apply the spray to the leaf in question and observe the degree of wetting. A difficult-to-wet leaf will remain dry or will have some droplets perched as perfect spheres on top of the leaf. An easy-to-wet leaf will make contact with the droplets.

Deposit Formation

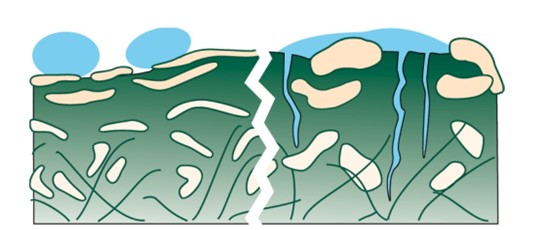

Another important part of obtaining good weed control is helping the absorption of herbicide through the plant’s barriers of entry. The most important of these barriers is the leaf cuticle, a layer of waxes that the plant uses to protect itself from the environment (Figure 6). This waxy layer is composed of films, or deposits that resemble rods, spheres, cubes, or platelets, depending on the species and age. Wax builds up in response to environmental conditions during the plant’s development, and as one might expect, more waxes are deposited under sunny, dry, and hot conditions. Greater wax buildup has been related to reduced herbicide uptake, although some studies have suggested that the type of wax may be just as important as the amount. Wax type and amount differ greatly among species, among plant regions, and with plant age, so it is difficult to always find the best surfactant for the job. The leaf cuticle responds to relative humidity, becoming more permeable under high humidity conditions. Spraying under these conditions has often resulted in better product performance.

When a droplet lands on a leaf, the water rapidly evaporates, leaving the non-volatile ingredients on the leaf surface. Herbicide uptake is driven by diffusion, the movement of substance from an area of high concentration to low concentration, and it is much easier for a liquid than a dry deposit to diffuse across a barrier. The most effective way to slow drying is to use larger droplets that simply take longer to evaporate, but formulations that can slow the drying of droplets may also enhance uptake under these conditions. Oily products that are formulated as emulsifiable concentrates become milky when added to water and are thought to slow evaporation. Unfortunately, there is little research information available that provides guidance on which registered adjuvants would provide the lowest evaporation.

Fertilizers as Water-Conditioning Adjuvants

Some fertilizers can be useful adjuvants for two reasons: they can overcome the antagonism posed by hard water, and they can enhance the uptake of some herbicides by plant cells. AMS (21-0-0-24) is the top water conditioning adjuvant, delivering the best performance for the cost. AMS contains two useful ions that fulfill important functions. The sulfate ions (SO4- -) bind with Ca++, Mg++, Na+, K+, and Fe+++ in hard water, preventing them from inhibiting the activity of herbicides which are susceptible to antagonism from these ions. Ammonium ions (NH +) help some herbicides cross plant cell membranes, enhancing the ion-trapping effect by which these active ingredients are absorbed and translocated by cells. Many Group 1 products, Roundup®, Group 2 products, amine formulations of Group 4 products, Liberty®, and Group 27 (Infinity®) are examples of herbicides that benefit from the inclusion of ammonium sulfate. UAN (28-0-0) is a liquid fertilizer that has some beneficial properties. Overall, 28-0-0 has less ammonium than ammonium sulfate (7% vs. 21%) and contains no sulfate. Do not expect 28-0-0 to reduce the effect of hard water, but due to its ammonium ions, it can improve herbicide uptake as seen when used with Viper and Basagran applications in peas. Always be careful about unintended consequences such as leaf burn on sensitive crops.

There are two basic approaches to using AMS to condition hard water. The first is a threshold approach. Research conducted at the University of Saskatchewan (USASK) has shown that water containing less than 350 ppm of total hardness does not require the addition of AMS for the half-litre per acre rate equivalent of glyphosate (700 ppm for the litre/acre equivalent). But above this threshold, the addition of up to 3% w/v AMS can correct the problem. Reduction of carrier volumes is also helpful.

The second approach is to look closely at the water test result and determine the exact amount of AMS needed. North Dakota State University has done much research in this area and has developed a formula The amount of AMS needed to overcome antagonistic ions in the spray solution is pounds AMS per 100 gallon = (0.002 * ppm K) + (0.005 * ppm Na) + (0.009 * ppm Ca) + (0.014 * ppm Mg) + (0.042 * ppm Fe).

If a water test shows high hard water cations, also consider using an alternate source of water, or using the maximum recommended rate of herbicide.

The presence of high levels of bicarbonate (HCO -) in some water can antagonize the Group 1 “dim” herbicides (Poast®, Centurion®). Using the maximum recommended herbicide rate, or 1.6 L/acre liquid ammonium sulfate (0.8 kg/acre 21-0-0-24 dry), or 0.2 L/acre 28-0-0, can overcome these problems according to research at the USASK.

The Bottom Line

Adjuvants are essential tools that ensure or enhance the activity of pesticides. Activator adjuvants are always included in product formulations or recommended on product labels. They lower surface tension, which can reduce droplet bounce and enhance droplet spread. In addition, they can increase herbicide absorption through cuticles and enhance the herbicide’s ability to withstand adverse environmental conditions such as rain or bright sunshine. Because of the very specific way in which adjuvants affect spray atomization, deposition, and uptake, it is not possible to predict how any one adjuvant will interact with the many factors that govern weed control without extensive experimentation. As a result, it is important to stick to label recommendations to ensure reliable product performance.

Utility modifier adjuvants are playing an increasing role in for pulse growers. Their role as water conditioners ensures the expected performance of herbicides with lower-quality water, and the low-drift adjuvants are proven to extend the conditions under which pesticides can be applied. Nonetheless, it remains important to make informed decisions so that unnecessary expenses can be avoided.

Tom Wolf is a professional agrologist with Agrimetrix Research & Training.