By Bruce Barker, P.Ag.

Protein from pulse and soybean seed is undergoing increased demand and interest. In 2018, the protein supercluster, Protein Industries Canada, received $153 million in funding to develop new protein opportunities in pulse and oilseed crops in areas of crop production, novel processing and formulation, and new market development. One of those new markets is the movement to plant-based protein in food products.

Peas and soybeans are currently of most interest from a protein perspective because of protein’s value in food and livestock feed.

In Saskatchewan, protein in peas is reported in the Government of Saskatchewan’s Varieties of Grain Crops 2019 publication. The check variety to which all other varieties are compared is CDC Amarillo, with a mean protein content of 23%. Protein content within peas differs by variety and ranges from 21.1-25.8% (Table 1).

Plant breeders hope to include protein content by variety for soybeans and possibly faba beans in the Saskatchewan variety guide in the next few years. Protein content in other pulse crops is not a focus from a buyer/marketing perspective at this time, and therefore has not been tested at a variety level.

Table 1. Typical Protein Levels in Pulse and Soybean Crops

| Crop | Protein Content (%)1 | Canadian Grain Commission 20222 %; range; (10-year average) |

|---|---|---|

| Soybeans | 26 – 40 | 38.9 |

| Faba Beans | 28 – 32 | na |

| Chickpeas | 17 – 24 | na |

| Peas | ||

| Yellow | 21.1 – 23.7 | 23.1; 16.8 – 30.5 (22.8%) |

| Green | 22.6 – 25.8 | |

| Red | 24 | |

| Maple | 22 – 24.9 | |

| Dun | 24.7 | |

| Forage | 25.2 | |

| Lentils | na | 26.4; 22.0 – 30.0 (26.9%) |

| Dry Beans | 22 – 24 | na |

1Adapted from the Government of Saskatchewan’s Varieties of Grain Crops and Saskatchewan Pulse Growers’ soybean regional variety trial data.

2Canadian Grain Commission 2022 data.

*na – data not available

Anatomy of Pulse Seed

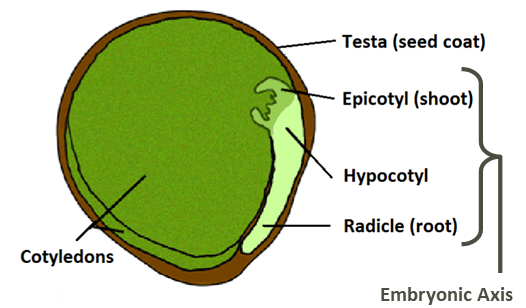

Mature pulse seed (Figure 2) contains the embryo which is enclosed by the seed coat (testa). The embryo is made up of two large cotyledons and the embryonic axis (epicotyl, hypocotyl, and radicle). The large storage cotyledons make up a big part of the seed’s volume and weight and contain the majority of the protein. In mature pulse seed there is very little endosperm as it degrades as the developing embryo uses up its resources during development.

In peas and lentils, about 90% of the protein is contained in the cotyledons, while the embryonic axis and seed coat combined contribute less than 10%. Other pulses have similar concentrations of protein in their respective parts.

Protein Development in Pulses vs Cereals

Source: Adapted from Finch-Savage, W & G. Leubner-Metzger. 2006. Seed dormancy and the control of germination. New Phytologist. 501-523.

With pulses, as the seed develops and matures, carbohydrates such as starches and sugars are deposited first followed by proteins. This differs from cereal grains where protein is deposited first followed by starches and sugars. This means environmental conditions and agronomic practises may influence protein levels differently between pulses and cereals.

Under good growing conditions, protein content in the seed fully develops in both cases. However, with pulses where the protein is laid down last, environmental conditions that are unfavourable may result in less ability to develop protein resulting in lower protein levels. Whereas for cereal crops in dry years, protein content is laid down first and limited moisture restricts the development of carbohydrates, resulting in a higher percentage of protein and lower percentage of carbohydrate.

There is still a lot that is unknown regarding the effects of environment on protein levels in pulse seed, but the following factors can contribute to a reduction in total protein in pulse seed:

- An early fall frost stops grain filling

- Cold temperatures during seed development in August

- Drought – may impact nitrogen fixation or seed fill

Influencing Protein Content

The biggest driver of protein content is nitrogen. Protein is roughly 16% nitrogen, so adequate nitrogen is critical to high protein content. For pulses and soybeans, adequate nitrogen means maximizing nodulation and nitrogen fixation through inoculation with the appropriate Rhizobium species, ensuring good survival of the inoculant during handling, and applying at the right rates.

Any agronomic practice that encourages good overall plant health, including balanced phosphorus, potassium, and sulfur nutrition, will encourage nitrogen fixation and high protein content in pulses and soybeans.

Several research studies have shown the importance of inoculant formulation and nitrogen fixation on protein content. The most recent trial was conducted by the Indian Head Agricultural Research Foundation (IHARF) with sites at Melfort, Indian Head, and Outlook, Saskatchewan over three years from 2015-2017. Funded by SPG, the research looked at benefits of inoculation and various nitrogen fertilizer strategies on soybean production. The results of the IHARF project generally indicate that optimal management for both yield and protein are similar. When inoculation was adequate, starter or

in-crop nitrogen was not beneficial and starter nitrogen sometimes led to lower seed protein concentrations.

In an Agriculture and Agri-Food Canada research trial in the Peace River region of Alberta in the mid-90s, pea protein concentration increased by 12% when a granular inoculant was soil-applied, compared with seed-applied peat or liquid inoculants. In the absence of nitrogen fertilizer, soil-applied granular inoculant increased pea seed yield and protein concentration, and contributed to increasing yield stability compared with seed-applied inoculant. Additionally, when nitrogen fertilizer was applied at rates up to 80 kilograms nitrogen per hectare (N/ha) as side-banded urea, regardless of inoculant form, the nitrogen fertilizer increased vegetative growth but did not affect yield or protein content.

Variety selection is also an important factor in protein content. As protein markets emerge, pulse and soybean growers should look to variety guides and seed companies for protein ratings in their area. This is especially important for growers who have had lower protein content than average, and who are seeking to avoid protein discounts.

Selecting varieties that are adapted to the local growing environment will also help ensure adequate grain fill during the optimum period in later summer.

Protein Markets

For soybeans, the main use is livestock feed with protein found in the meal as the main component. Lower protein content from prairie soybeans may become a concern in some markets as lower protein content in the seed translates to lower protein content of the meal after oil extraction.

Feed peas and faba beans are also used as a source of protein for livestock feed. In the future, this market for protein might require specific levels of protein or place a dollar value on protein levels.

Pulse processing and fractionation plants who are targeting products with higher protein or protein concentrates may also have minimum protein levels in the future or premiums for higher protein seed.

Testing for Protein in Pulses

Combustion (Dumas) and Kjeldahl Method are used to determine the protein content of food and seed, however for both methods, the seed must be ground prior to analysis.

Kjeldahl Method is regarded as a standardized method to determine the percent protein of food and food ingredients, but it is time consuming. A sample is heated and ‘digested’ with sulphuric acid that releases nitrogen as ammonium sulphate. The amount of nitrogen released is used as an indication of protein content. Most proteins contain 16% nitrogen, which means the amount of nitrogen released multiplied by 6.25 (nitrogen conversion factor) equals protein content percentage.

The Combustion method is convenient so it is more widely used to measure protein percentage and protein fractions. A seed sample is combusted with oxygen and gases containing nitrogen oxides are collected. Nitrogen is measured and converted to protein percentage using the 6.25 conversion factor.

The nitrogen conversion factor used has not been standardized for different types of commodities although the range between foods is relatively narrow. The conversion factor in foods range from 6.38 for dairy and 6.25 for meat, eggs, corn, sorghum, and navy bean, 5.83 for most grains, 5.95 for rice, 5.71 for soybeans, and 5.46 for peanuts. In the absence of verified conversion factors for many crops, 6.25 is still used as the conversion factor for pulses, soybeans, and other crops.

The CGC uses the Combustion method according to the AOAC method 992.23 to determine the crude protein content of pulses and soybeans. The results are expressed as a dry weight basis.

For growers who participate in the CGC’s Harvest Sample Program, the results provided back to growers includes protein content on barley, beans, chickpeas, lentils, peas, and soybeans. Growers will also receive an unofficial grade.

At the University of Saskatchewan’s Crop Development Centre (CDC), plant breeders use near infrared spectroscopy to measure protein content in pulses and soybeans. Foss NIR DS2500 is used to predict protein in peas and a Foss Infratec Nova NIT to predict protein in chickpeas, faba beans, dry beans, and soybeans. NIR testing takes about one minute to measure protein content in the seed, and the seeds do not have to be ground as they are in the Combustion and Kjeldahl methods. At the CDC, they also use the Dumas Combustion method to improve the NIR calibration accuracy on an on-going basis.

In a survey of grain buyers, NIR equipment is used to measure protein content, with technologies from companies such as FOSS and Perten. Generally, grain buyers have not tested pulses for protein content, and purchase according to CGC grading standards, which does not require protein testing. However, this may change as more emphasis is placed on protein for human and livestock food. An exception is that some soybean grain buyers are testing for protein content.

In Summary

To maximize protein in pulses and soybeans in Western Canada:

- Choose varieties with higher protein levels

- Choose varieties that have the right maturity for your region

- Maximize nodulation with appropriate inoculants, formulations, and rates

- Manage nutrients to ensure no deficiencies are encountered (with a particular emphasis on

phosphorus for enhanced maturity)

Soybean Protein Content

Soybean protein content on the Prairies is lower than in other parts of the world. Compared to the mid-west of the United States and southern Ontario, protein content drops as production moves north and west. Increased scrutiny on protein content in Saskatchewan and Manitoba soybeans has resulted in soybean buyers to downgrade low protein soybeans by up to 32% in previous years.

Canadian Grain Commission (CGC) data shows that western Canadian soybeans are generally lower in protein than eastern Canadian soybeans but the gap has been narrowing (Figure 1). Ten years ago, western Canadian soybeans were generally 3-4% lower in protein content than eastern Canadian soybeans. This spread has narrowed to around 2%. However, CGC data shows that there is a range of protein content. In Western Canada, the mean protein level in No. 1 and No. 2 soybeans was 38.5%, with a range of 36-40%.

Source: Canadian Grain Commission

Research has not yet identified the reason for lower soybean protein content on the Prairies. As shown in Figure 1, protein content varies year-to-year, suggesting environmental conditions have a large impact on protein content. Another possible reason is that breeding for high yield and earlier maturity has sacrificed protein content.

Protein content can vary by variety so there is some genetic component to protein content as well. Most research with varieties has demonstrated a strong variety by environment correlation for protein content. The details in terms of environmental factors and genes involved have yet to be determined and there are a number of research projects currently underway to shed more light into what controls the protein levels.

Current research indicates that growers can employ few managment practices to maximize their seed protein potential:

- Ensure the soybean crop has sufficient nitrogen, up to 50 lb/ac, as well as adequately inoculated, can improve amino acid composition and seed protein content.

- Soybean crops produced on fields with diverse crop rotations have been shown to produce higher protein content seed compared to soybeans grown in tighter crop rotation systems according to research conducted at Kansas State University.

- General best management practices such as no-till, targeting ideal soil temperatures and early planting when possible, lower target plant populations, using seed treatments, correct herbicide application timing and fungicides when needed were all shown to aid in seed protein content.

- Seed selection. Maturity group ratings were not found to significantly influence seed protein content in northern US, but longer maturing varieties tended to set higher protein in the southern US. Therefore choosing the correct soybean variety for your growing region (aka growing degree days) is more important for harvest management and other downgrading factors such as green seed and the risk of frost damage.

Protein content of soybean varieties from Saskatchewan Regional Variety Trials is available on Saskatchewan Pulse Growers’ (SPG) website.