Pulse crops grown in Western Canada are able to fix much of their nitrogen requirements from gaseous nitrogen found in the soil atmosphere surrounding the root hairs. This is done through a beneficial relationship between a pulse crop and soil Rhizobium bacteria.

Why Inoculate?

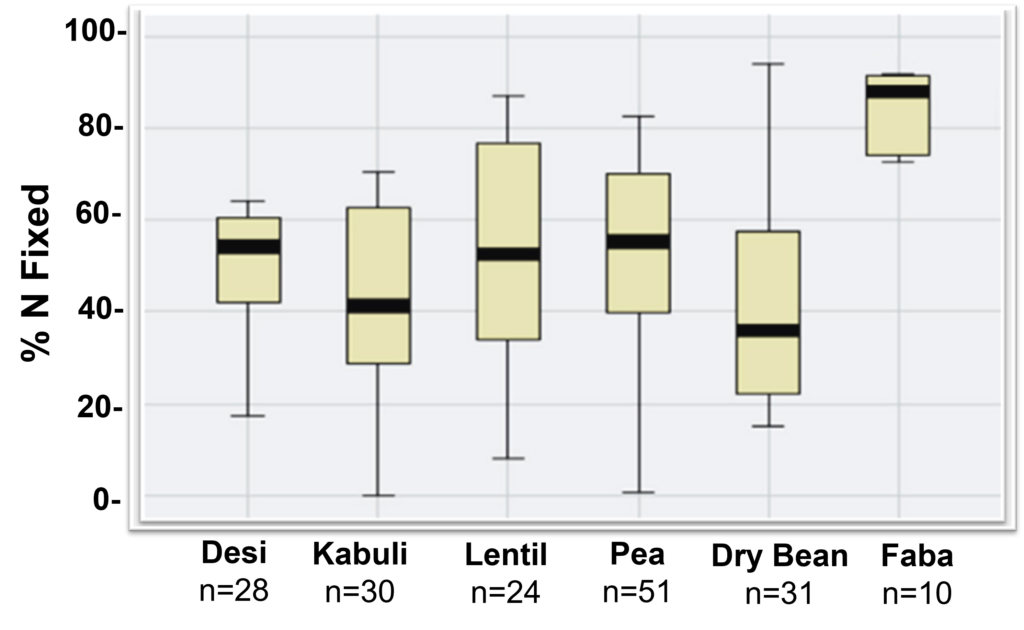

Research by Dr. Fran Walley at the University of Saskatchewan (USask) found that pulse crops inoculated with the proper Rhizobium have the potential to fix 50–80% of their nitrogen requirement through nitrogen fixation, although the amount varies by crop. For example, faba beans were found to fix around 90% of their requirements, while dry beans were less than 40%. Generally, pulse crops are ranked by their estimated nitrogen-fixing ability: faba beans > peas > chickling vetch > chickpeas > lentils > soybeans > lupin > dry beans.

Rhizobia live freely in the soil and can persist for several years even in the absence of a pulse crop. However, even though the rhizobial community may be present in the soil, native strains may not be the most effective nitrogen fixers, and introduced strains may lose their ability to fix nitrogen. Additionally, the rhizobia bacteria that form a relationship with chickpeas and soybeans are not native to Western Canadian soils. As a result, inoculating pulse seed with rhizobia bacteria will lead to optimal nitrogen fixation and yield. Inoculation ensures that the most effective strain is present in sufficient numbers near the root zone to maximize nodulation.

Rhizobium Inoculant Species

The data was compiled from published research reports and papers.

The thick, dark line indicates the median value; the box represents 50% of all data; and the whiskers contain the remaining 50%.

Source: Dr. Fran Walley, University of Saskatchewan

An inoculant carries a specific Rhizobium species that matches the pulse crop. Choose the correct species for each crop.

Table 1. Rhizobium Species Required for Pulse Crops

| Crop | Species |

|---|---|

| Peas, Lentils, Faba Beans | Rhizobium leguminosarum |

| Chickpeas | Rhizobium ciceri |

| Dry Beans | Rhizobium phaseoli |

| Soybeans | Bradyrhizobium japonicum Bradyrhizobium elkanii |

Inoculating Pulse Crops with Rhizobium

Inoculation is the process of introducing nitrogen-fixing bacteria onto the seed or into the soil close to the seed to ensure successful nodulation. The bacteria must come into contact with the developing seedling for infection of the root hairs to occur, thereby initiating nitrogen fixation. Table 2 lists the products available.

Rhizobium Inoculant Formulations

Inoculants come in several different formulations. The choice of inoculant formulation depends on application convenience and, in some cases, performance.

Peat-Based Powder

Rhizobium bacteria are contained within a peat-based powder carrier. They can be applied as a dry powder directly to the seed or in a water slurry, which helps with seed adherence. Peat-based formulations are more challenging to handle and apply to seeds than liquid formulations. Some peat products require a sticker if it is not already included in the formulation (i.e., self-sticking formulations). Commercial sticker products are available if needed. An advantage of peat over liquids is its ability to retain moisture, which can help prevent desiccation of rhizobia on the seed, especially when conditions at seeding are dry. Peat-based formulations can be made from either sterile or non-sterile peat and may differ in their acceptance by organic certifying bodies.

Liquid-Based

Rhizobium bacteria are contained in a liquid formulation, which is applied directly to the seed to achieve a desired rhizobial population per seed. Some liquid inoculants are also registered for application directly in the seed row, as in-furrow applications. Liquid inoculants are easy to use and much less messy compared to peats. Stabilizers and extenders help protect rhizobia in the liquid formulations.

Granular-Based

Rhizobium bacteria are formulated into granules that are applied directly into the furrow, close to the seed. Granular formulations differ in the carriers used and range from peat-, to clay-, to synthetic-based granules. The product application rates are based on applying a specific weight per area or per row, which requires a higher volume of material to be handled compared to peat or liquid applications. Applying it through seeding equipment enables accurate applications and reduces mess compared to seed-applied inoculants. Granular inoculants provide protection for rhizobia against the elements. Some manufacturers also allow side-banding of a granular inoculant. A separate tank and meter are required. Do not mix and apply with fertilizer.

Pre-Inoculated Seed

The seed is treated with a peat-based or liquid inoculant encapsulated in a seed coating at a commercial facility prior to purchase. No further inoculation is required, and this formulation provides a longer shelf life (often weeks) for the viability of the inoculant on seed compared to direct seed inoculation on-farm (hours or days).

Double Inoculation with Rhizobium

Research in Manitoba and Saskatchewan has shown a yield benefit from double inoculation in first- and second-time soybean fields. Typically, a liquid or peat inoculant is seed-applied along with a granular or liquid in-furrow application.

A three-year study conducted at the Indian Head Agricultural Research Foundation (IHARF), with sites at Indian Head and Melfort, found a highly significant yield response to a liquid inoculant applied to the seed and a granular inoculant applied in-furrow at the recommended label rate. At these sites with no previous soybean history, there were strong yield responses to dual inoculation with a mean overall yield increase of 7.4 bushels per acre (497 kilograms per hectare) or 24%. At the Outlook site, which had a history of soybean production in two previous rotation cycles, there was no practical benefit to dual inoculation.

On fields where soybeans have been grown previously, Manitoba Pulse and Soybean Growers provides a checklist for growers to determine whether dual inoculation is necessary. The IHARF research suggests that Saskatchewan soybean growers could also follow this checklist when deciding whether to continue double inoculation. When all of the following conditions are met, single inoculation is likely to be sufficient:

- The field has had at least two previous soybean crops

- Previous soybean crops have nodulated well

- The most recent soybean crop was within the past four years

- No significant flooding or drought

No benefit from double inoculation has been observed in lentils, peas, faba beans, or chickpeas. However, if soils have been flooded or have not received a pulse in many years, the native rhizobial population may be low, so double inoculation can help ensure good nodule establishment, though at a high additional cost.

Inoculant Performance

All inoculants deliver rhizobia bacteria into the soil, so all can be successful if the bacteria multiply, colonize the roots, and ultimately cause nodulation. However, there are circumstances in which some formulations do a better job of keeping rhizobia alive. Generally, granular products are more resilient to stressful conditions (such as dryness and heat), but even granular formulations can fail if the conditions simply do not allow the bacteria to survive.

Research at Agriculture and Agri-Food Canada (AAFC) Indian Head and AAFC Melfort evaluated inoculant formulations in peas. When soil moisture conditions were below normal, the granular formulation performed better than the seed-applied peat-based powder, which in turn performed better than the seed-applied liquid formulation. However, when soil moisture was normal, and soil organic matter levels exceeded 6%, no difference was found among formulations.

Similar results were found in USask research on chickpeas. Peat-based and liquid inoculants were applied directly to the seed, and granular inoculants were applied either in the seed row or placed in a sideband, 2.5 centimetres (cm) or one inch (in) to the side and at depths of either 2.5 or 8 cm (1 or 3 in.) below the seed. The peat-based powder and liquid formulations performed as well as the granular formulation, usually when soil moisture was not limited. Under drier soil conditions, granular products usually outperformed the seed-applied formulations.

In research conducted at AAFC Brandon and AAFC Indian Head, liquid inoculant formulations were evaluated for their performance as a soil treatment when applied either as a dribble into the seed row or as a sideband.

Treatments included a liquid formulation suspended in a water solution, applied to the soil, a granular formulation applied to the soil, a liquid formulation applied to the seed, and an untreated check. The soil-applied liquid and granular formulations performed equally, and all formulations and application methods resulted in increased seed yield compared to the non-inoculated check.

Placement of Rhizobium Inoculant

Rhizobium bacteria infect root hairs where the inoculant is placed. The roots need to come into contact with rhizobia; therefore, placing the inoculant too far from the emerging roots can delay the development of nodules and the initiation of nitrogen fixation. As a result, seed row placement of granular inoculants is generally recommended.

Sideband placement, approximately one inch below and one inch to the side of the seed, may be effective. However, not all manufacturers recommend sideband placement, and high fertilizer rates in the same band may harm the bacteria. Contact the manufacturer for recommendations specific to sidebanding inoculants.

Placement in a mid-row banding is not a suitable option, as late infection and nodulation could delay nitrogen fixation, especially under dry conditions.

Rhizobia tend to form nodules close to where the bacteria are placed, so seed-placed inoculants lead to a more significant portion of nodules forming close to the crown area on the main tap root and lateral roots close to the inoculant placement. Soil-applied granular inoculants tend to form nodules on lateral roots closer to where the granules were delivered in or near the seed row.

Other Microorganisms & Additives

In addition to Rhizobium bacteria, some inoculants contain supplementary organisms and compounds that may enhance nitrogen fixation or provide other benefits to the crop (Table 2).

Plant growth-promoting rhizobacteria (PGPRs) grow in the root zone (rhizosphere) and can stimulate plant growth through various mechanisms, including increased availability, mobility, and uptake of nutrients by the plant. PGPRs include bacterial species such as Pseudomonas, Azotobacter, Enterobacter, Alcaligenes, Arthrobacter, Azospirilum, Klebsiella, Burkholderia, Bacillus, and Serratia. Some Rhizobium inoculant products are also packaged with PGPRs.

Fixing nitrogen requires a significant amount of energy from the plant. This energy comes from photosynthesis and is transferred in the root zone through a coenzyme called adenosine triphosphate (ATP).

Phosphorus is a key component of this coenzyme, and therefore, proper phosphorus uptake is crucial for providing the energy needed to fix nitrogen. Some microorganisms are known to enhance phosphorus uptake. Penicillium bilaiae, for example, is a fungus that produces organic acid that breaks the link between phosphorus and calcium in high-pH soils and other bacteria.

Arbuscular mycorrhizal fungi (MF) are another group of organisms that form symbiotic relationships with plants such as pulses. They grow on plant roots and spread into the root tissue, forming a network that helps the roots access more nutrients and water, acting as extensions of the root system. Healthier plants exhibit improved stress resistance and the ability to tolerate certain pathogens. MF are present in the soil, but products can also be seed-applied to increase their presence, such as those containing the fungus Rhizophagus irregularis (previously known as Glomus intraradices).

Biological fungicides are a newer class of organisms that include specific species and strains with activity against pests and pathogens. With inoculants, there is increasing interest in combining them with biofungicides to help keep roots healthy. Organisms that have been registered with biofungicidal properties include Bacillus amyloliquefaciens strain MBI 699 (Integral®) for partial suppression of seedling diseases caused by Fusarium spp. and Rhizoctonia spp.

Lipo-chitin oligosaccharides (LCOs) are another type of additive found in select products. The nodulation process begins when the pulse root secretes flavonoids, which are sensed by the rhizobia. In response, the rhizobia produces its signal, known as the Nod factor, which is returned to the plant. The plant then responds by allowing the root hairs to be infected by the rhizobia. These Nod factors, also known as LCOs, can be included in some inoculants.

Gluconacetobacter diazotrophicus (Gd) is a bacterium isolated from sugarcane. The patented strain (Envita®) enables most crops, including pulses, cereals, and canola, to fix nitrogen. Like rhizobia, Gd utilizes the nitrogenase enzyme to fix nitrogen. However, instead of fixing nitrogen in root nodules outside of the plant, Gd systemically enters the roots, stems, and leaves of the crop and fixes nitrogen inside plant cells. A rhizobia inoculant should be used in combination with Envita®. Gd fixes nitrogen quickly and can do so before rhizobium root nodules form. Envita does not affect nodule formation or reduce rhizobia efficacy, and it can be applied in-furrow or as a foliar application.

Biological products and additives can be confusing regarding registration processes and label claims. Inoculants sold in Canada are registered under The Fertilizers Act administered by the Canadian Food Inspection Agency. Many of the additives are also registered through this same process. Additives or biologicals with fungicidal activity or pest control label claims are registered under the Pest Control Act, administered by the Pest Management Regulatory Agency.

Limited independent research has been conducted on some of these organisms or compounds. Pulse growers are advised to leave check strips when using products with these additional additives to assess their value.

Seed Treatment Compatibility

Seed treatments (fungicides and insecticides) differ in their impact on inoculant viability. Always read and follow product labels, and contact your inoculant manufacturer for guidelines on the proper use of combinations of seed treatments and seed-applied inoculants. Sequential application, in which the seed treatment is applied to the seed and allowed to dry before the inoculant is applied, is usually the safest method.

Table 2. Seed Treatment Compatibility

| Company | Label (click for compatibility link) |

|---|---|

| BASF | Nodulator® LQ (liquid) – soybean |

| Nodulator® XL (liquid & peat) – pea, lentil | |

| BrettYoung | BrettYoung Inoculant Products Compatibility |

| Lallemand | LALFIX – pea, lentil |

| FMC | FMC Inoculant Compatability |

| NutriAg | BOS™ |

| PremierTech | AGTIV® inoculant products |

| Verdesian | https://vlsci.com/wp-content/uploads/2023/12/Verdesian-Canada-Inoculant-Compatibility-Chart_4.10.23.pdf |

| XiteBioTechnologies Inc. | PulseRhizo® |

| SoyRhizo® | |

| Yield+ | |

| OptiPlus® |

Storage and Handling

For all formulations, inoculants contain living bacteria and must be stored under conditions that maintain their viability. Keep cool and out of direct sunlight. Follow manufacturer recommendations for storage. Check the product expiry date, which displays when the number of live bacteria is no longer guaranteed.

Once the seed is treated with a liquid or peat inoculant, it should be sown promptly. Try to treat only the amount of seed that can be planted in one day without leaving the product overnight in the nurse truck or air seeder compartment.

Although nitrogen-fixing inoculants are generally non-toxic, protective equipment, including gloves, goggles, and an approved respirator, is recommended. When mixed with seed treatment fungicides and insecticides, follow handling and safety recommendations for those products.

Table 3. Inoculant Options for Pulse Crops

| Product | Company | Description | Non Nitrogen-Fixing Technology1 | Crops | Formulation | Organic Acceptance4 | |||||||

| Peas | Lentils | Faba Beans | Chickpeas | Soybeans | Dry Beans | Liquid | Peat | Granular | |||||

| Atuva™ PL | Syngenta | Rhizobium leguminosarum biovar viceae | Osmo Protector | X | X | X | X | ||||||

| Cell-Tech® Pea/Lentil | FMC | R. leguminosarum | X | X | X | X2 | X | ||||||

| Nodulator® Duo SCG | BASF | R. leguminosarum bv. viceae + Bacillus subtilis | PGPR | X | X | X | |||||||

| Nodulator® XL | BASF | R. leguminosarum bv. viceae | X | X | X | X | |||||||

| TagTeam® Pea/Lentil | FMC | R. leguminosarum + P. bilaiae | P | X | X | X | X | ||||||

| AGTIV FUEL® Pea/Lentil | Premier Tech (Taurus) | R. leguminosarum bv. viceae | X | X | X | X | X | X | Yes | ||||

| AGTIV THRIVE® Pea/Lentil | Premier Tech (Taurus) | R. leguminosarum bv. viceae + Rhizophagus irregularis | MF | X | X | X | X | X | X | Yes | |||

| BOS™ Pea/Lentil/Faba Bean | NutriAg | R. leguminosarum bv. viceae + Pseudomonas sp. | PGPR + P + BGP | X | X | X | X | X | X | ||||

| Exceed® Traditional | Visjon | R. leguminosarum bv. viceae | X | X | X | X | Yes | ||||||

| LALFIX® LIQUID Pea/Lentil | Lallemand Plant Care | R. leguminosarum bv. viceae (dual strains) | X | X | X | X | |||||||

| LALFIX® PEAT Pea/Lentil | Lallemand Plant Care | R. leguminosarum bv. viceae (dual strains) | X | X | X | X | |||||||

| LALFIX® GR Pea/Lentil | Lallemand Plant Care | R. leguminosarum bv. viceae (dual strains) | X | X | X | X | |||||||

| LIFT-Kit® Pulse | Verdesian | R. leguminosarum + Azospirilium brasilense + Take Off® | PGPR + N catalyst | X | X | X | X | ||||||

| N-Charge® Pea/Lentil/Faba Bean | Verdesian | R. leguminosarum bv. viceae | X | X | X | X2 | |||||||

| N-Dure® Pea/Lentil/Faba Bean | Verdesian | R. leguminosarum bv. viceae | X | X | X | X2 | Yes | ||||||

| N-Row® Pea/Lentil/Faba Bean | Verdesian | R. leguminosarum bv. viceae | X | X | X | X | |||||||

| N-Take™ Pea/Lentil/Faba Bean | Verdesian | R. leguminosarum bv. viceae | X | X | X | X | |||||||

| Osmium™ Pea/Lentil | BrettYoung | R. leguminosarum bv. viceae | Osmo Protector | X | X | X | X | ||||||

| TagTeam® BioniQ® Pea/Lentil | FMC | R. leguminosarum + Penicillium bilaiae + Bacillus amyloliquefaciens + Trichoderma virens + lipochitooligosaccharide | P + LCO + PGPR | X | X | X | X | ||||||

| XiteBio® PulseRhizo® | XiteBio Technologies Inc. | R. leguminosarum + AGPT® | AGPT® | X | X | X | X | Yes | |||||

| Exceed® Granulated Peat | Visjon | R. leguminosarum bv. viceae + Mesorhizobium ciceri | PGPR | X | X | X | X | X | |||||

| Exceed® Stic | Visjon | R. leguminosarum bv. viceae + M. ciceri | X | X | X | X | X | Yes | |||||

| LALFIX® START PULSES GR | Lallemand Plant Care | R. leguminosarum bv. viceae + M. ciceri + Bacillus velezensis | PGPR + P | X | X | X | X | X | |||||

| Primo GX2 | Verdesian | R. leguminosarum bv. viceae + M. ciceri + A. brasilense | PGPR | X | X | X | X | X | |||||

| AGTIV THRIVE® Chickpea | Premier Tech (Taurus) | M. ciceri + R. irregularis | MF | X | X | X | |||||||

| Exceed® Traditional | Visjon | M. ciceri | X | X | Yes | ||||||||

| LALFIX® PEAT Chickpea | Lallemand Plant Care | M. ciceri | X | X | |||||||||

| N-Charge® Chickpea | Verdesian | M. ciceri | X | X2 | |||||||||

| N-Dure® Chickpea | Verdesian | M. ciceri | X | X2 | Yes | ||||||||

| Nodulator® CP SCG | BASF | M. ciceri | X | X | |||||||||

| Osmium™ Chickpea | BrettYoung | M. ciceri | Osmo Protector | X | X | ||||||||

| Primo | Verdesian | M. ciceri | Extender | X | X | ||||||||

| TagTeam® BioniQ® Chickpea | FMC | M. ciceri + P. bilaiae + B. amyloliquefaciens + T. virens | P + PGPR | X | X | ||||||||

| TagTeam® Chickpea | FMC | M. ciceri + P. bilaiae | P | X | X | ||||||||

| AGTIV ENRICH® Soybean | Premier Tech (Taurus) | Bradyrhizobium japonicum + B. subtilis | PGPR | X | X | ||||||||

| AGTIV FUEL® Soybean | Premier Tech (Taurus) | B. japonicum | X | X | X | Yes | |||||||

| AGTIV THRIVE® Soybean | Premier Tech (Taurus) | B. japonicum + R. irregularis | MF | X | X | X | X | Yes | |||||

| Atuva™ S | Syngenta | B. japonicum | X | X | X | ||||||||

| BOS™ Soybean Inoculant | NutriAg | B. japonicum + Pseudomonas sp. | PGPR + P + BGP | X | X | X | |||||||

| Cell-Tech® Soybean | FMC | B. japonicum | X | X | X | X | |||||||

| Exceed® Granular | Visjon | B. japonicum | X | X | |||||||||

| Exceed® Peat | Visjon | B. japonicum | X | X | |||||||||

| Exceed® Traditional | Visjon | B. japonicum | X | X | |||||||||

| LALFIX® LIQUID Soybean | Lallemand Plant Care | B. elkanii | X | X | |||||||||

| LALFIX® PEAT Soybean | Lallemand Plant Care | B. elkanii (dual strains) | X | X | |||||||||

| LALFIX® PROYIELD Liquid Soybean | Lallemand Plant Care | B. elkanii (dual strains) + Delftia acidovorans | PGPR + Fe solubilizing | X | X | ||||||||

| LALFIX® GR Soybean | Lallemand Plant Care | B. japonicum (dual strains) | X | X | |||||||||

| LALFIX® START GR Soybean | Lallemand Plant Care | B. elkanii (dual strains) + B. velezensis | PGPR + P | X | X | ||||||||

| Launcher™ Soybean | BrettYoung | B. japonicum | X | X | |||||||||

| N-Charge® Soybean | Verdesian | B. japonicum | X | X2 | |||||||||

| N-Dure® Soybean | Verdesian | B. japonicum | X | X2 | Yes | ||||||||

| N-Take™ Soybean | Verdesian | B. japonicum | X | X | |||||||||

| N-Row® Soybean | Verdesian | B. japonicum | X | X | |||||||||

| Nodulator® IP Plus | BASF | B. japonicum + B. amyloliquefaciens + B. subtilus | PGPR | X | X3 | ||||||||

| Nodulator® LQ | BASF | B. japonicum | X | X | |||||||||

| Nodulator® PRO 100 | BASF | B. japonicum + B. amyloliquefaciens | PGPR | X | X | ||||||||

| Nodulator® SCG | BASF | B. japonicum | X | X | |||||||||

| Optimize® FXC DS | FMC | B. japonicum (multiple strains) + lipochitooligosaccharide | LCO | X | X | ||||||||

| Preside® Ultra | Verdesian | B. japonicum (multiple strains) + A. brasilense | PGPR | X | X | ||||||||

| Primo GX2 Soybean | Verdesian | B. japonicum (multiple strains) + A. brasilense | PGPR | X | X | ||||||||

| Primo R1 | Verdesian | B. japonicum | X | X | |||||||||

| Signum® Soybean | BrettYoung | B. japonicum | Osmo Protector & Bio-Inducer | X | X | ||||||||

| TagTeam® Soybean | FMC | B. japonicum + P. bilaiae | P | X | X | ||||||||

| XiteBio® OptiPlus® | XiteBio Technologies Inc. | B. japonicum + AGPT® + Bacillus firmus | AGPT® + P + PGPR | X | X | Yes | |||||||

| XiteBio® SoyRhizo® | XiteBio Technologies Inc. | B. japonicum + AGPT® | AGPT® | X | X | ||||||||

| BOS™ Dry Bean | NutriAg | R. leguminosarum bv. phaseoli + Pseudomonas | PGPR + P + BGP | X | X | ||||||||

| Exceed® Dry Bean | Visjon | R. leguminosarum bv. phaseoli | X | X | |||||||||

| N-Charge® Dry Bean | Verdesian | R. leguminosarum bv. phaseoli | X | X | |||||||||

| N-Dure™ Dry Bean | Verdesian | R. leguminosarum bv. phaseoli | X | X2 | |||||||||

1 PGPR (plant growth-promoting rhizobacteria); AGPT® (advanced growth-promoting technology); LCO (lipochitooligosaccharide); P (phosphate solubilizing or enhancing); MF (mycorrhizal fungi); BGP (biological growth promoter)

2 Non-sterile peat option or only non-sterile peat

3 For professional treaters only, provides 100 days on-seed viability

4 Product(s) are available in formulations that meet organic standards. Check with the company for more information and certifications.

Last updated February 2026